Crafting Quality: Your Guide to Modern Bar Soap Production Lines

The demand for high-quality bar soap, whether for personal care (toilet soap) or household use (laundry bar soap), remains strong. Meeting this demand efficiently requires reliable and well-designed soap making production lines. These integrated systems transform raw materials into finished, stamped bars ready for market. Understanding the core components of an automatic soap production line is key for manufacturers aiming for consistency and scalability.

At the heart of any bar soap line is the soap mixer or mixing machine. This crucial stage blends fats, oils, alkali, and additives uniformly. Following mixing, the soap base undergoes refining, often involving an OEM three roller grinding mill to achieve a smooth texture essential for premium products like beauty soap. The refined soap mass is then fed into a soap plodder machine for bar soap, typically a vacuum plodder, which removes air pockets and compresses the soap into a solid, continuous log under vacuum conditions. This step is vital for producing dense, long-lasting bars.

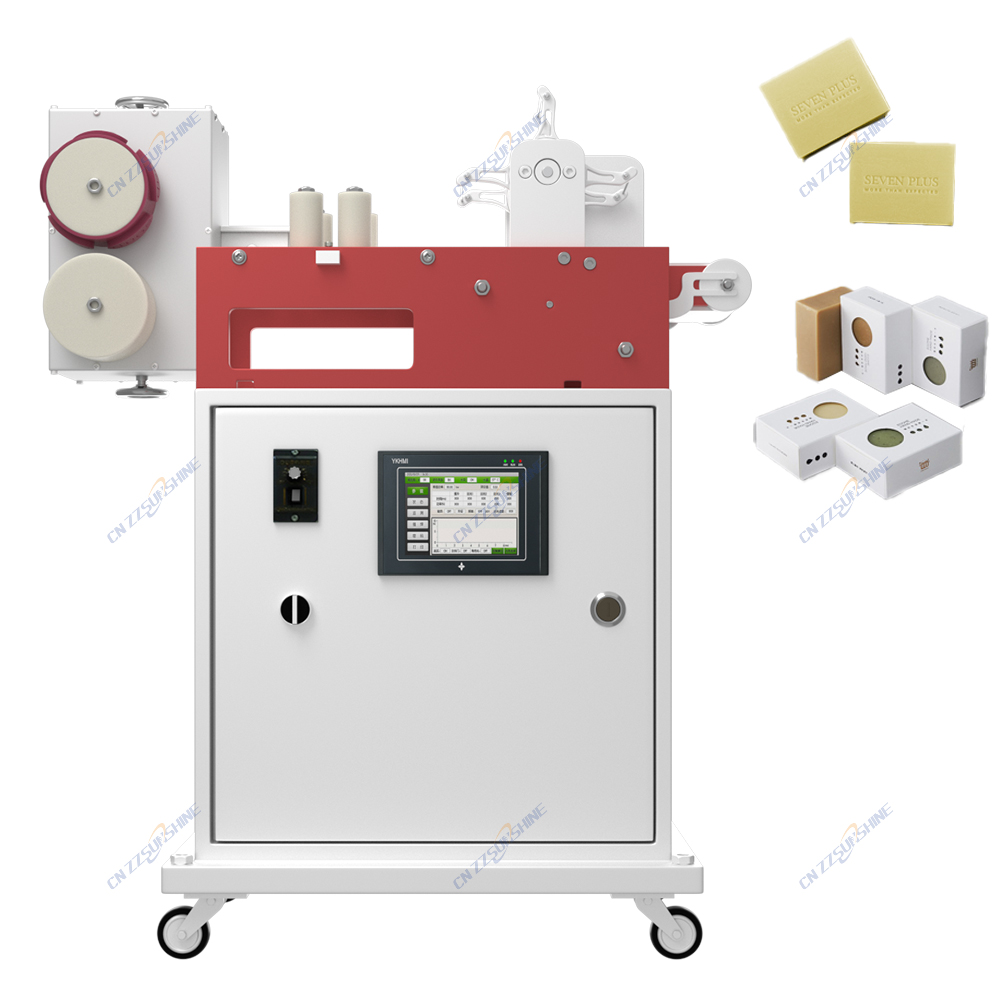

The extruded soap log then moves to cutting. Options range from manual cutting machine for very small batches to high-speed automatic block cutter machine units. Pneumatic cutting machine or electronic cutting machine offer precise, consistent sizing for both laundry bar soap production line and toilet soap finishing line operations. After cutting, individual soap pieces are stamped using an automatic printer or semi-automatic printer, often paired with a dedicated soap stamping machine to imprint logos or designs clearly.

Finally, the finished bars are packaged. A film packaging machine efficiently wraps each bar, protecting it and presenting it attractively for retail. Whether you require a comprehensive automatic soap production line or a more compact mini soap production line, modern machinery offers solutions tailored to specific output goals and bar types – from simple laundry soap making line to sophisticated bath soap making machine setups. Investing in the right combination of soap making machine components, including potentially a custom soap cutting machine, ensures efficient, high-quality bar soap manufacturing.