Streamlining Your Soap Production: The Efficient Full Automatic Palm Oil Soap Noodle Making Machine Production Line

The global demand for high-quality palm oil-based soaps continues to grow, placing pressure on manufacturers to increase output while maintaining consistency and reducing costs. Traditional methods often struggle to meet these demands efficiently. This is where a modern, efficient full automatic palm oil soap noodle making machine production line becomes a game-changer for businesses seeking a competitive edge.

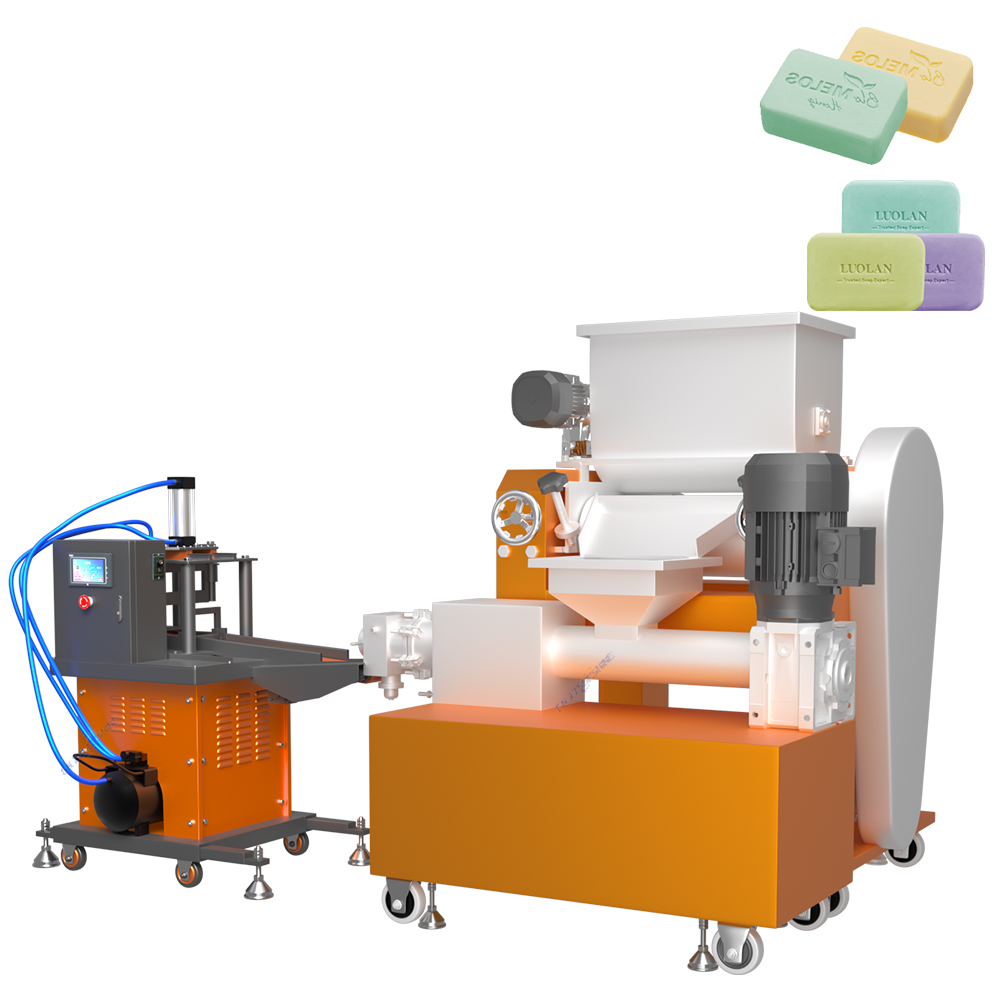

Designed specifically for processing palm oil into premium soap noodles – the fundamental base for countless bar soap varieties – this integrated system offers unparalleled efficiency. By automating the entire sequence from mixing raw materials to producing uniform, ready-to-process noodles, manufacturers can achieve significant gains in productivity and product quality.

Core Advantages of the Full Automatic Line

1. Unmatched Efficiency: Automation drastically reduces manual labor requirements and minimizes human error. Continuous operation ensures a steady flow of output, maximizing your production capacity.

2. Consistent Quality: Key components like the soap plodder machine, especially a high-grade vacuum plodder, ensure thorough mixing, de-aeration, and extrusion under controlled conditions. This results in dense, homogenous soap noodles with uniform texture and moisture content, essential for producing flawless finished bars. Precision automatic block cutter machines guarantee noodles of exact dimensions.

3. Cost Reduction: Reduced labor costs, minimized material waste due to precision cutting and controlled processes, and lower energy consumption compared to running multiple standalone machines contribute to a healthier bottom line.

4. Scalability & Flexibility: Whether you operate a mini soap production line or a large-scale laundry bar soap production line or toilet soap finishing line, these automated systems can be scaled to fit your needs. They can often be customized (custom soap cutting machine, specific OEM three roller grinding mill settings) to handle various soap formulations and final product specifications.

5. Hygiene & Safety: Enclosed systems and automated handling improve hygiene standards and enhance operator safety by reducing direct contact with materials and moving parts.

Key Components Driving Performance

Advanced Mixing: The process begins with robust soap mixer or mixing machine technology, ensuring palm oil, caustic soda, and other additives are blended homogeneously.

Precision Refining: Optional OEM three roller grinding mill units can be integrated for refining the soap mass before plodding, crucial for high-clarity toilet soaps.

Vacuum Plodding: The heart of noodle quality. A vacuum plodder removes air pockets, compacts the soap, and extrudes a smooth, continuous log under vacuum, significantly improving the final bar’s lather and longevity.

Automated Cutting: High-speed automatic block cutter machines (which could be electric washing soap cutter, pneumatic cutting machine, or electronic cutting machine types) slice the extruded log into precise, uniform noodles with minimal waste. This eliminates the bottlenecks and inconsistencies of manual cutting machines.

Integrated Control: Modern PLC systems allow for precise control over temperatures, pressures, speeds, and cutting parameters, ensuring repeatable results batch after batch.

Investing in Your Future

Integrating an efficient full automatic palm oil soap noodle making machine production line is a strategic investment. It empowers manufacturers to meet rising demand efficiently, produce superior quality palm oil soap noodles consistently, reduce operational costs, and ultimately enhance profitability. For businesses focused on laundry soap making lines, toilet soap finishing lines, or specialized beauty soap making lines, this automation provides the reliable, high-volume base material essential for success. Explore how this technology can transform your soap making production line today.