Your Complete Guide to Small-Scale Soap Production Lines (50kg/h – 150kg/h)

Establishing a reliable, efficient soap manufacturing operation, whether for laundry bars, bath soaps, or beauty soaps, requires the right machinery. For small to medium-scale producers targeting outputs between 50kg/h and 150kg/h, finding a streamlined and cost-effective soap making production line is key. This often involves sourcing directly from manufacturers for better value and tailored solutions.

A typical compact laundry bar soap production line or toilet soap finishing line integrates several core machines. The process usually begins with a robust soap mixer or mixing machine to blend saponified paste and additives uniformly. For refining texture, an OEM three roller grinding mill is essential. The heart of forming solid bars lies in a soap plodder machine for bar soap, often a vacuum plodder to ensure dense, bubble-free extruded logs. Following extrusion, an automatic block cutter machine precisely slices the soap log into individual billets.

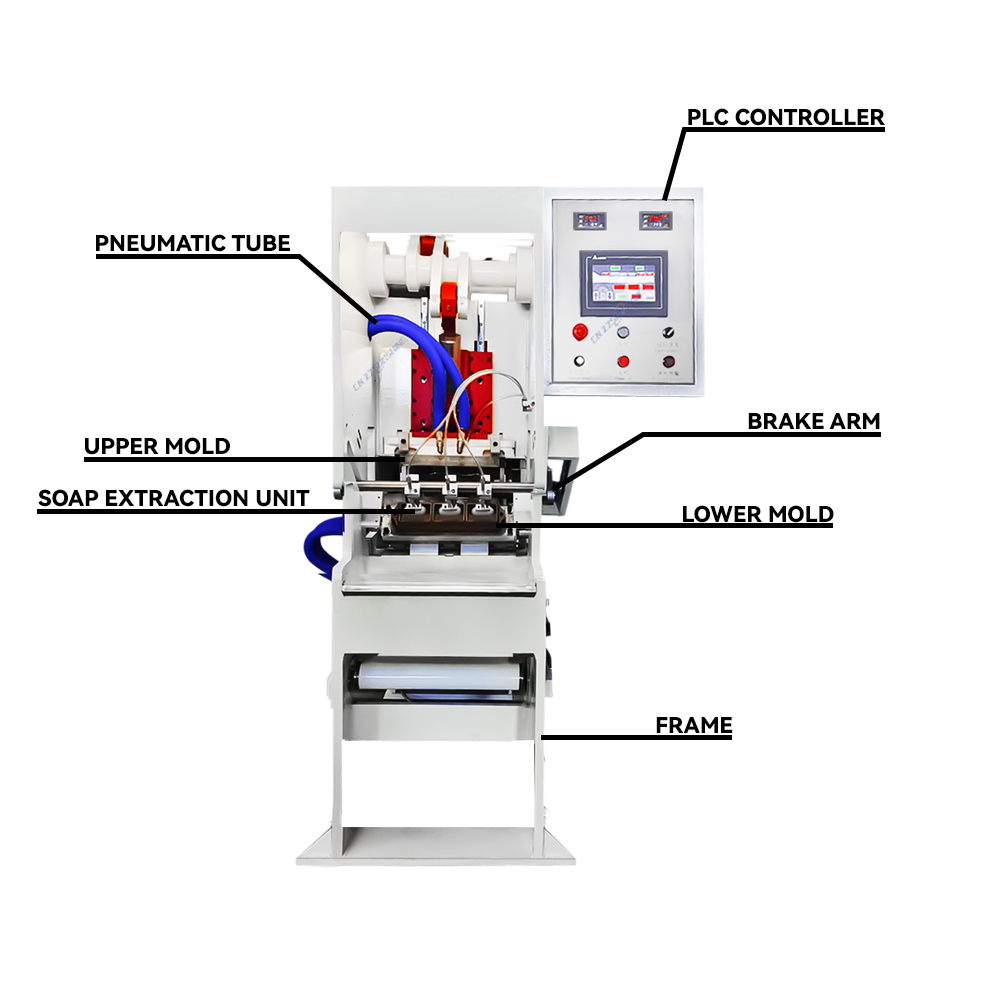

Further processing depends on the product. A soap stamping machine imparts branding, while a film packaging machine or semi-automatic printer provides wrapping. Cutting options range from manual cutting machines to faster electronic cutting machines or pneumatic cutting machines, ensuring flexibility. For those seeking higher automation, components like an automatic printer can be integrated into a semi-automatic or fully automatic soap production line.

Choosing a factory direct supply solution offers significant advantages, particularly for custom soap cutting machine needs or tailored mini soap production line configurations. Manufacturers can adapt core equipment – the soap plodder, cutter, and mixer – to specific requirements, ensuring the line efficiently meets the desired 50kg/h to 150kg/h capacity. This direct approach simplifies procurement and provides access to expertise for setting up an effective soap making machine line.

Investing in a well-designed production line streamlines operations, enhances product quality, and supports scalable growth for your soap manufacturing business.