Finding Value in Quality: Made-In-China Soap Making Machines & Plodder Price Insights

If you’re sourcing reliable soap production equipment, you’ve likely encountered “Made-In-China Soap Making Machine,” “Bar Soap Making Machine,” and “Soap Plodder Machine Price” in your research. Chinese manufacturers offer compelling value, but understanding what drives the price is crucial for informed decisions. Let’s explore the key factors influencing cost, particularly for core components like the soap plodder machine.

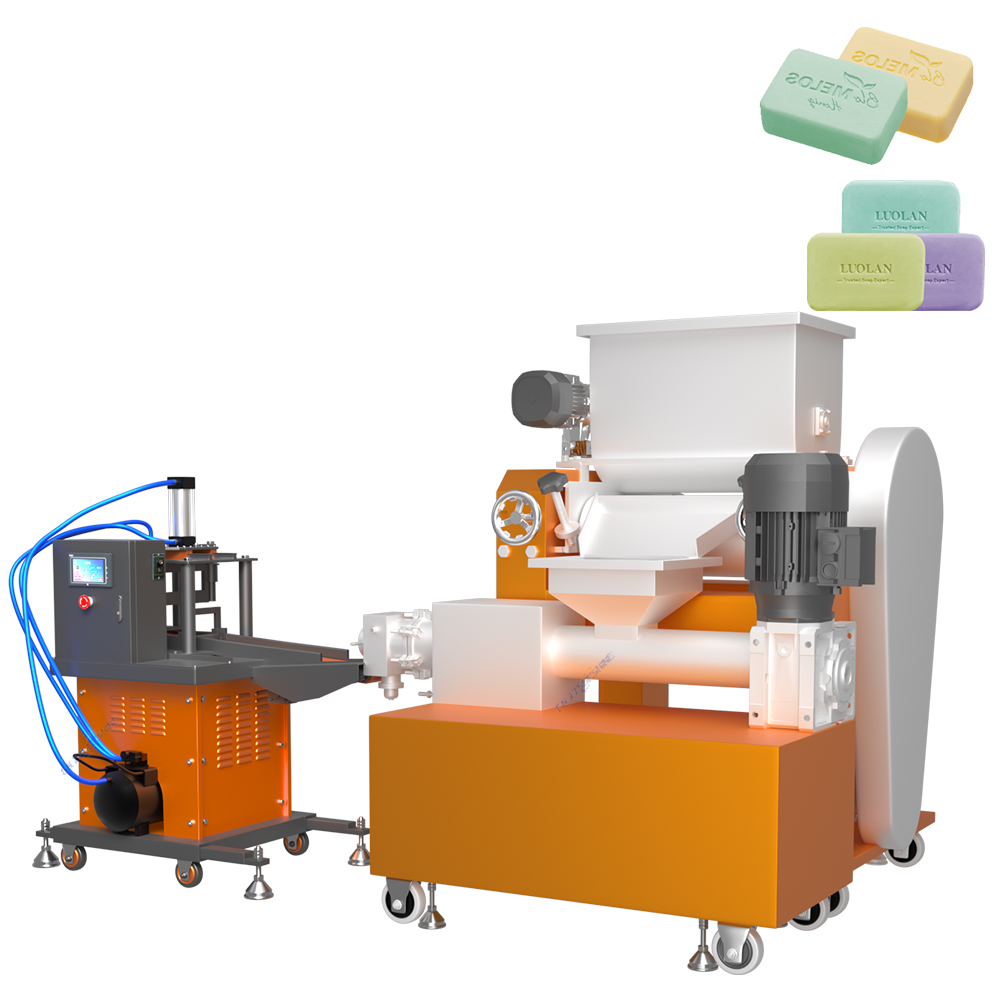

A robust soap making machine line is built on critical units. The soap mixer or mixing machine initiates the process, blending ingredients uniformly. Next, the soap plodder, often a vacuum plodder, is vital. This machine refines the soap mass, removes air, and extrudes a solid, consistent noodle or bar base. The quality of the plodder directly impacts the final bar’s texture and density. Following extrusion, cutting becomes essential. Options range from manual cutting machines to sophisticated automatic block cutter machines or pneumatic cutting machines, designed for precision and efficiency in high-volume laundry bar soap production lines or toilet soap finishing lines.

Beyond the core soap plodder machine for bar soap, prices are influenced by several factors. The level of automation is paramount – a fully automatic soap production line commands a higher investment than semi-automatic setups or mini soap production lines. Customization also plays a role; custom soap cutting machine designs or specific OEM requirements (like an OEM three roller grinding mill for specialty pastes) will affect cost. Additional components such as soap stamping machines or film packaging machines add functionality but also to the overall price tag. Finally, the machine’s build quality, materials used, and the manufacturer’s reputation for reliability are significant price determinants.

Chinese manufacturers offer diverse solutions, from basic semi-automatic printers to comprehensive automatic soap production lines with automatic printers. While price is a major consideration, ensure you’re evaluating the total value proposition – equipment durability, efficiency, and the supplier’s support capabilities. By understanding the core technologies like the soap plodder and the factors affecting its price, you can make a smarter investment in your bath soap making machine or laundry soap making line. Reach out to reputable suppliers for detailed quotes based on your specific needs.