Good Quality Multi-function New Product 2024: Small Machines for Toilet Soap Manufacturing

Looking to start or upgrade your soap production? The right machinery is crucial for efficiency, quality, and meeting growing market demands. For businesses focused on crafting premium toilet soaps, especially those operating on a smaller scale or looking for versatile solutions, 2024 brings exciting advancements in compact, multi-function equipment. These new machines offer the performance you need without requiring massive floor space or investment.

Modern soap making machine technology, particularly for toilet soap finishing lines, has evolved significantly. Manufacturers now offer highly efficient mini soap production lines designed for entrepreneurs and small to medium enterprises. These lines often incorporate key components like a robust soap mixer or mixing machine to ensure consistent blending of ingredients. Following mixing, a soap plodder machine for bar soap, often a compact vacuum plodder, refines the texture, removes air pockets, and extrudes a smooth, dense soap noodle.

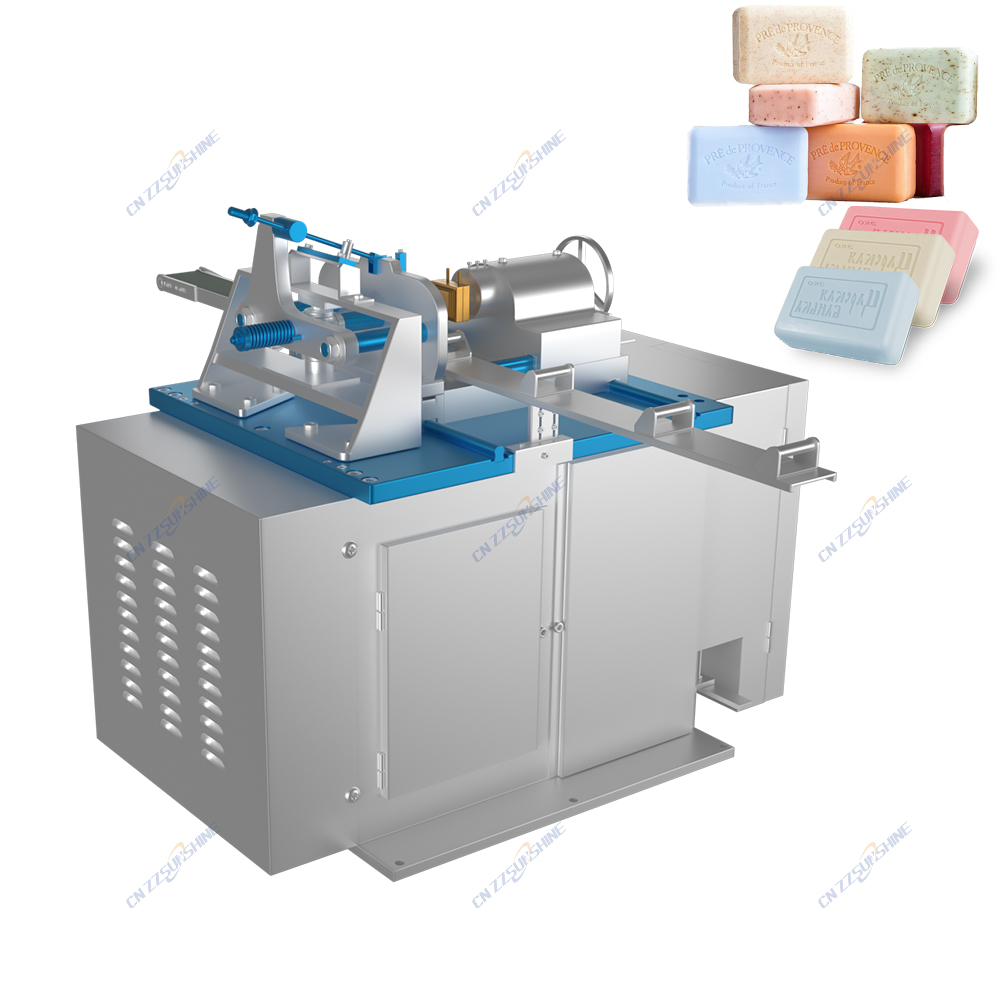

The extrusion is then processed by precise cutting equipment. Options range from manual cutting machines for very small batches to electronic cutting machine or pneumatic cutting machine systems offering greater speed and consistency. An automatic block cutter machine or custom soap cutting machine can be integrated for high-volume output. For finishing touches, a semi-automatic printer or automatic printer, along with a soap stamping machine, brands each bar professionally. Finally, a film packaging machine seals the product for hygiene and presentation.

Why choose these newer, smaller soap making production line options? They deliver good quality results consistently. Their multi-function designs often allow for flexibility – potentially handling both toilet soap finishing lines and smaller-scale laundry bar soap production lines or bath soap making machine tasks with adjustments. They are engineered for reliability and easier operation. Furthermore, many manufacturers support OEM configurations or offer custom soap cutting machine solutions to fit specific needs.

Investing in a modern, compact soap making machine or integrated automatic soap production line is a smart move for 2024. These systems empower businesses to produce high-quality toilet soaps efficiently, adapt to market changes, and grow their brand reputation. Explore the latest innovations in small-scale soap manufacturing technology to find the perfect fit for your operation.