The Heart of Smooth Bars: How a Three Roller Machine Elevates Your Soap Production Line

For anyone serious about crafting high-quality bar soap, achieving that perfect, smooth texture is non-negotiable. It’s what defines a premium product and delights customers. That’s where the often-underestimated three roller machine proves its immense value within a robust soap making production line. Its job? To refine your soap mass to an unparalleled degree of fineness.

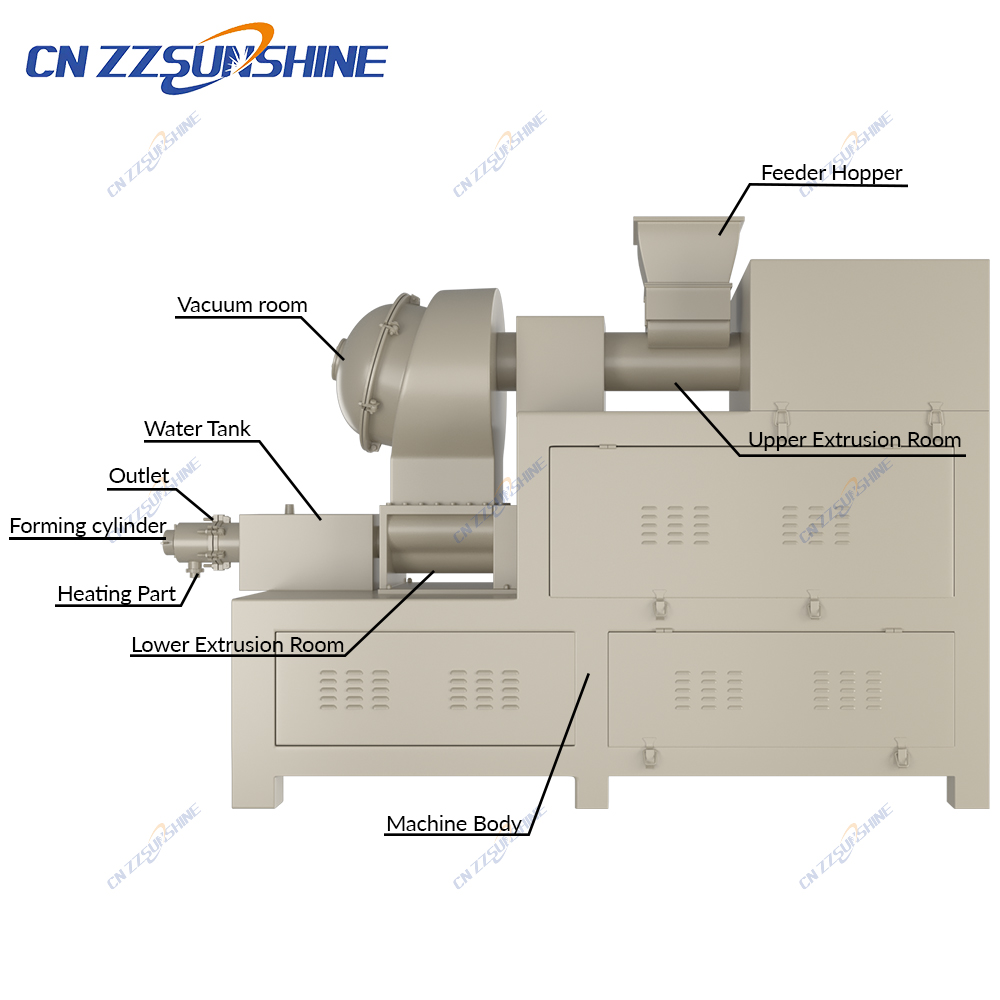

Think of the soap production journey: it starts with blending oils and lye in a powerful soap mixer. Once saponified, the soap base moves into a vacuum plodder, where it’s compressed, de-aerated, and extruded into a continuous log. This log is then precisely cut into individual bars using an automatic block cutter machine. Next comes stamping with an automatic soap stamping machine and packaging, often facilitated by a reliable film packaging machine.

But here’s the crucial step that elevates the entire process: feeding the mixed soap base through the three roller mill before it enters the plodder. This OEM three roller grinding mill works by passing the soap mixture between three precisely spaced, rotating rollers. Each pass progressively refines the soap, breaking down any remaining coarse particles or undispersed ingredients. The result? A significantly smoother, more homogeneous paste.

Why does this matter so much? Finer grinding directly translates to:

Superior Lather: A smooth bar creates a richer, more luxurious lather.

Enhanced Feel: The bar feels silkier against the skin.

Improved Appearance: Eliminates graininess for a polished, professional look.

Better Extrusion: A uniform paste flows more consistently through the soap plodder machine for bar soap, leading to higher output and fewer production hiccups in your laundry soap making line or toilet soap finishing line.

Integrating a high-quality three roller machine isn’t just an addition; it’s an investment in the fundamental quality of your soap. Whether you’re running a large-scale automatic soap production line or a smaller mini soap production line, ensuring your soap mass is ground finely is paramount. It’s the silent workhorse that makes the difference between a good bar and a truly exceptional one, setting your product apart in a competitive market.