Beyond Suds: Powering Your Bar Soap Production with Automation

The demand for high-quality bar soap, encompassing everything from laundry staples to luxurious bathing bars, remains consistently strong. Meeting this demand efficiently and profitably requires moving beyond manual methods. Investing in an automatic soap production line, specifically designed for capacities like 100-150kg/h, transforms your operation from a bottleneck into a powerhouse. This article explores the core components and advantages of such a system, focusing on the journey from raw materials to finished, stamped bars.

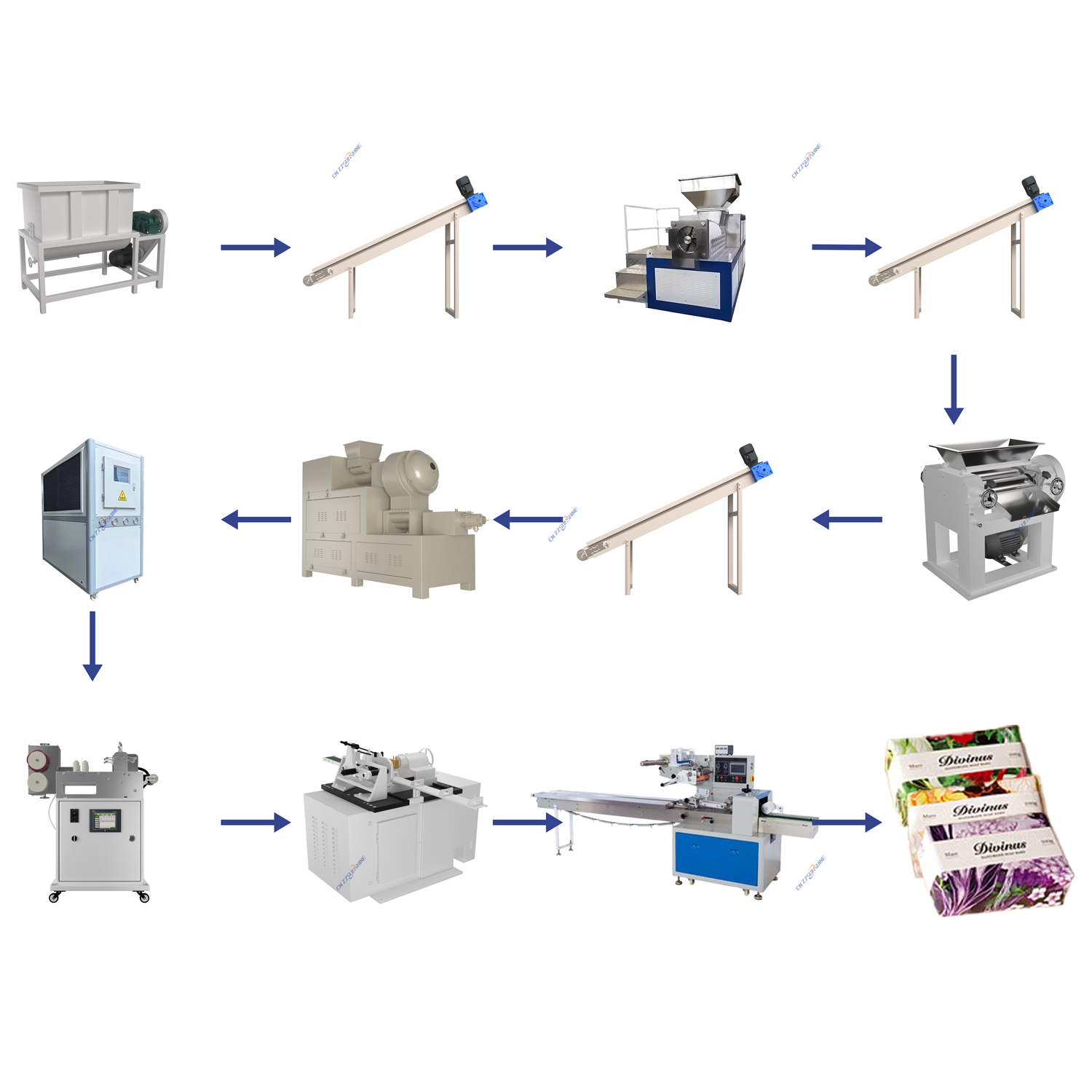

The Heart of the Line: Efficient Mixing and Refining

Every great bar starts with a homogenous blend. A robust soap mixer or mixing machine is the starting point, ensuring fats, alkalis, additives, and fragrances are uniformly combined. This foundational step is critical for consistent saponification and final product quality. Following mixing, achieving the desired texture often involves refining the soap mass. An OEM three roller grinding mill plays a pivotal role here, meticulously smoothing the mixture, removing air pockets, and preparing it for extrusion. This step is vital for producing a smooth, dense bar that lathers well and feels pleasant.

Shaping the Bar: Extrusion and Cutting Precision

The refined soap is then fed into a vacuum plodder. This sophisticated soap plodder machine for bar soap is arguably the most crucial component in a toilet soap finishing line or laundry bar soap production line. Operating under vacuum, it removes residual air, compresses the soap, and extrudes it through a die as a continuous, dense log or billet. The vacuum process is essential for preventing aeration, ensuring a hard, long-lasting bar with a fine grain. Following extrusion, the continuous soap log needs precise sizing. This is where an automatic block cutter machine shines. Whether utilizing pneumatic cutting machine or electric washing soap cutter mechanisms, this equipment slices the log into uniform, pre-weighed blocks with remarkable speed and accuracy, far surpassing manual methods.

Finishing Touches: Stamping and Packaging

The cut blocks then proceed to the soap stamping machine. This unit imparts your brand identity and any desired design onto the soap surface, adding significant value and marketability. Finally, the finished bars are ready for wrapping. A reliable film packaging machine efficiently applies protective film or flow-wrap, safeguarding the product during storage and transit while presenting it attractively on the shelf.

Why Automate Your Bathing Bar Soap Production Line?

Integrating an automatic soap production line like a 100-150kg/h solid laundry toilet soap making machine offers compelling advantages:

Increased Output & Efficiency: Automation dramatically boosts production rates (e.g., 100-150kg/h) and reduces labor dependency.

Enhanced Consistency & Quality: Machines ensure uniformity in weight, size, density, and finish, batch after batch, crucial for brand reputation.

Improved Safety: Automating repetitive tasks minimizes manual handling risks.

Scalability: Designed systems can often be upgraded or adjusted to meet growing demand.

Cost-Effectiveness: While an initial investment, automation lowers long-term per-unit production costs through efficiency and reduced waste.

Whether you’re focused on laundry soap making line efficiency or crafting premium beauty soap making line products, the core principles of automated production hold. From the initial soap mixer to the final automatic printer on the packaging, each component plays a vital role. By investing in a tailored soap making production line, manufacturers gain the robust, reliable, and high-capacity machinery needed to thrive in the competitive bar soap market. Explore custom soap cutting machine options and discuss your specific needs with equipment providers to find the optimal solution for your bath soap making machine requirements.