The Mini Marvel: Your Complete Solution for Small-Scale Soap Production

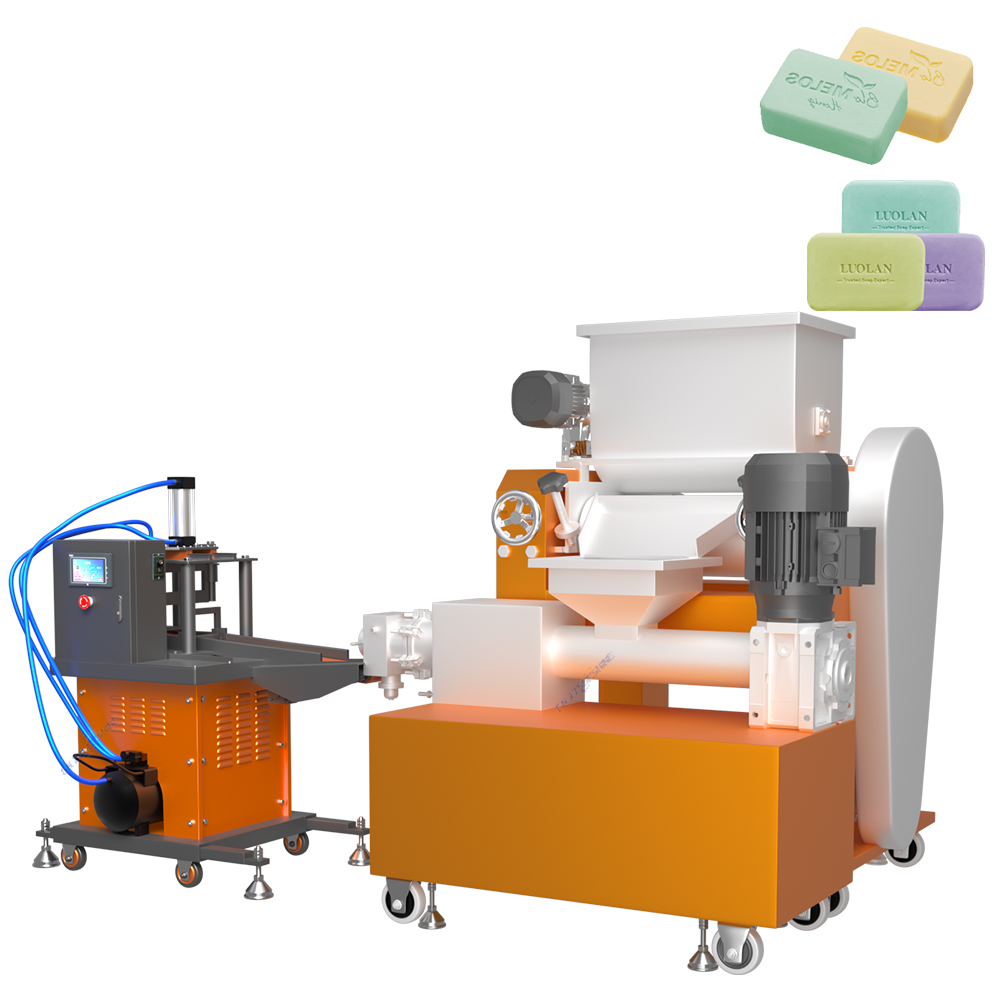

Dreaming of crafting high-quality laundry bar soaps or luxurious bath soaps but constrained by space or budget? Finding the right equipment for small-batch production can be a challenge. That’s where innovative, compact solutions like the Cheaper Bathroom Laundry Bar Soap Make Machine come into play. This Mini Vacuum Solid Soap Plodder Complete Line offers a surprisingly affordable and space-efficient entry point into professional soap manufacturing.

For artisanal producers, small businesses, or startups, investing in a full-scale industrial soap making production line is often impractical. Large Automatic soap production lines require significant capital and floor space. This is precisely why scaled-down, integrated systems are gaining traction. A well-designed Mini Soap Production Line packs the essential functionality into a manageable footprint, delivering professional results without the industrial overhead.

So, what does a compact, efficient line entail? Let’s break down the core components you’ll find in a robust setup designed for smaller outputs:

1. Mixing & Refining: It starts with a reliable soap mixer or Mixing machine to blend raw materials (fats, oils, lye, additives). For refining the soap mass to achieve a smooth texture, an OEM three roller grinding mill is often incorporated, working the soap through consecutive rollers for homogenization.

2. The Heart: Vacuum Plodding: This is crucial. A soap plodder machine for bar soap, specifically a Vacuum plodder, is the core. This machine compresses the mixed soap under vacuum conditions. Why vacuum? It removes air bubbles, resulting in a denser, harder, longer-lasting bar soap – essential for both laundry bar soap production line and toilet soap finishing line quality. The compact Mini Vacuum Solid Soap Plodder performs this vital function efficiently.

3. Extrusion & Cutting: The plodder extrudes a continuous, dense log of soap. This log then feeds into a cutting system. Options range from Manual Cutting Machines for ultimate flexibility to Electronic Cutting Machines or Pneumatic Cutting Machines for consistent, automated sizing. A custom soap cutting machine or automatic block cutter machine ensures bars are cut precisely to your desired weight and dimensions.

4. Finishing Touches: Depending on your product (laundry vs. beauty/bath), finishing may involve stamping and packaging. A Soap Stamping Machine imprints your brand logo. Packaging could involve simple hand wrapping or a compact Film Packaging Machine for efficiency. You might also find a Semi-automatic Printer or Automatic Printer for labeling.

The beauty of a complete line like this lies in its integration. Designed to work seamlessly together, these machines – the soap plodder, mixer, cutter, and potentially a small grinding mill – form a cohesive unit. This eliminates compatibility issues and streamlines your soap making machine workflow, whether you’re focusing on a laundry soap making line, a bath soap making machine setup, or a beauty soap making line.

Investing in a purpose-built Mini Vacuum Solid Soap Plodder Complete Line offers significant advantages:

Cost-Effective: Dramatically lower initial investment compared to large industrial lines.

Space-Saving: Fits into smaller workshops or production areas.

Professional Quality: Achieves the density and finish expected of premium bar soaps.

Flexibility: Adaptable for different soap types and batch sizes.

Efficiency: Integrated design minimizes handling and speeds up production.

For entrepreneurs and small manufacturers serious about producing top-tier bar soaps – be it robust laundry bars or elegant bath soaps – this compact, affordable technology provides the perfect launchpad. Why compromise on quality or scalability when a complete, miniaturized solution is within reach?