Crafting Quality: Inside the Soap Production Line

For entrepreneurs and established manufacturers alike, investing in efficient and reliable soap making machinery is paramount to producing consistent, high-quality bars. Whether your focus is on laundry bars, luxurious bath soaps, or beauty soaps, understanding the core components of a soap making production line is essential. This journey transforms raw materials into finished bars, with each machine playing a critical role.

The process often begins with the preparation of the soap base. Here, equipment like the soap mixer or a specialized mixing machine ensures homogeneous blending of fats, oils, alkali, and additives. For formulations requiring fine texture, an OEM three roller grinding mill might be employed to refine the mixture, creating a smooth paste ready for the next stage.

This prepared soap mass then moves to the soap plodder, a cornerstone machine. The vacuum plodder is particularly valued for its ability to extrude soap under vacuum conditions, removing air pockets and significantly enhancing the bar’s density, lather, and longevity. Whether it’s a robust soap plodder machine for bar soap in a large laundry bar soap production line or a more compact unit for a bath soap making machine setup, this extrusion step defines the soap noodle’s quality.

Following extrusion, the continuous soap noodle requires precise sizing. This is where cutting technology comes into play. While manual cutting machines exist for very low volumes, efficiency demands automation. Options range from electronic cutting machines and pneumatic cutting machines to the highly efficient automatic block cutter machine. For businesses seeking flexibility or operating a mini soap production line, a semi-automatic soap cutter offers an excellent balance, providing precise cuts with manageable investment and footprint. Specific needs might even call for a custom soap cutting machine or an electric washing soap cutter designed for particular bar dimensions or production speeds.

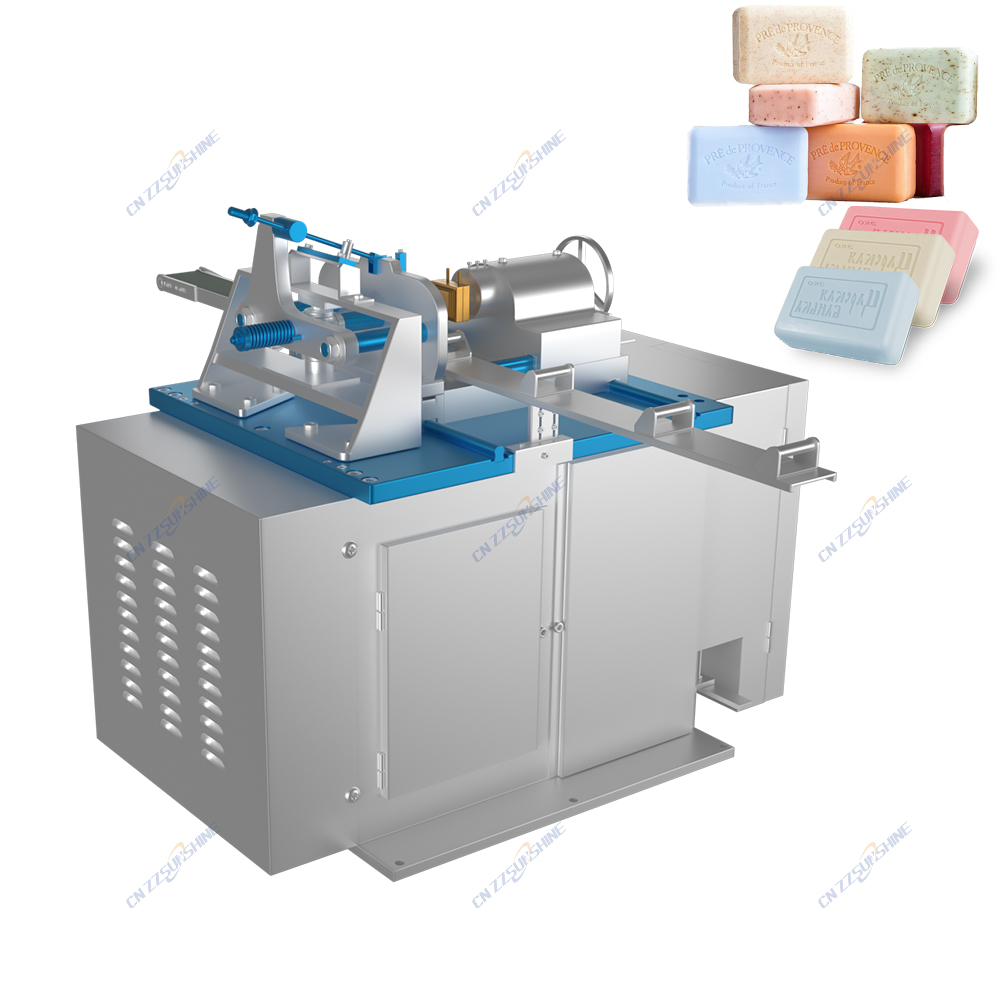

After cutting, the soap bars enter the finishing phase, crucial for branding and presentation. A soap stamping machine imparts logos, designs, or product information onto each bar. Depending on the line’s automation level, this could involve a semi-automatic printer or a fully integrated automatic printer. Finally, the finished bars are protected and prepared for market using a film packaging machine, ensuring hygiene and extending shelf life.

From the initial mixing in the soap mixer to the final packaging, each machine in the soap making machine ecosystem contributes to the final product’s quality and consistency. Whether you’re setting up a comprehensive automatic soap production line for high-volume toilet soap or laundry detergent bars, or a smaller beauty soap making line, selecting the right combination of machinery – including the indispensable soap plodder, efficient cutter, and reliable soap stamping machine – is key to operational success and market competitiveness.