The Unsung Hero of Superior Soap: Mastering Oil & Caustic Soda Mixing

In the intricate dance of soap manufacturing, where quality and consistency are paramount, one critical stage often holds the key to success: the precise blending of oils and caustic soda. This foundational step, known as saponification, isn’t just a chemical reaction; it’s the birthplace of the soap bar’s final characteristics – its lather, hardness, moisturizing properties, and overall performance. Achieving perfection here requires more than just dumping ingredients together. It demands a High Quality Mixing Machine for Liquid Soap Oil and Caustic Soda Making, a specialized soap mixing tank designed for the unique challenges of this volatile combination.

Why Standard Mixers Fall Short

Attempting this delicate balance with generic equipment is a recipe for inconsistency and potential hazards. Caustic soda (sodium hydroxide) is highly corrosive and reactive. Combining it with oils at incorrect temperatures or with inadequate mixing intensity can lead to:

Incomplete Saponification: Resulting in free alkalinity, causing skin irritation in the final product.

“Soap Boiling Over”: A dangerous and messy overflow if the reaction isn’t controlled.

Uneven Texture & Performance: Streaks, soft spots, or poor lathering due to inconsistent blending.

Safety Risks: Handling highly caustic materials without proper containment and mixing control endangers operators.

The Essential Role of a Dedicated Soap Mixing Tank

A purpose-built mixing machine for liquid soap oil and caustic soda addresses these critical issues head-on. These are not mere agitators; they are engineered systems designed for safety, efficiency, and batch uniformity. Key features often include:

Robust Construction: Typically high-grade stainless steel (like 304 or 316L) to withstand corrosion from caustic soda and ensure longevity.

Precision Temperature Control: Jacketed tanks allow for heating or cooling to maintain the optimal temperature range for the saponification reaction, preventing runaway reactions and ensuring complete neutralization.

High-Efficiency Agitation: Powerful, specially designed impellers create thorough, homogenous mixing without introducing excessive air (which can lead to voids in the finished soap bar). This ensures every molecule of oil reacts uniformly with the caustic soda.

Safety Features: Secure lids, proper venting, and often integrated safety interlocks protect operators during the potentially hazardous mixing phase.

Scalability: Available in various sizes, from smaller units suitable for pilot batches or niche producers to large tanks integral to a full laundry bar soap production line or toilet soap finishing line.

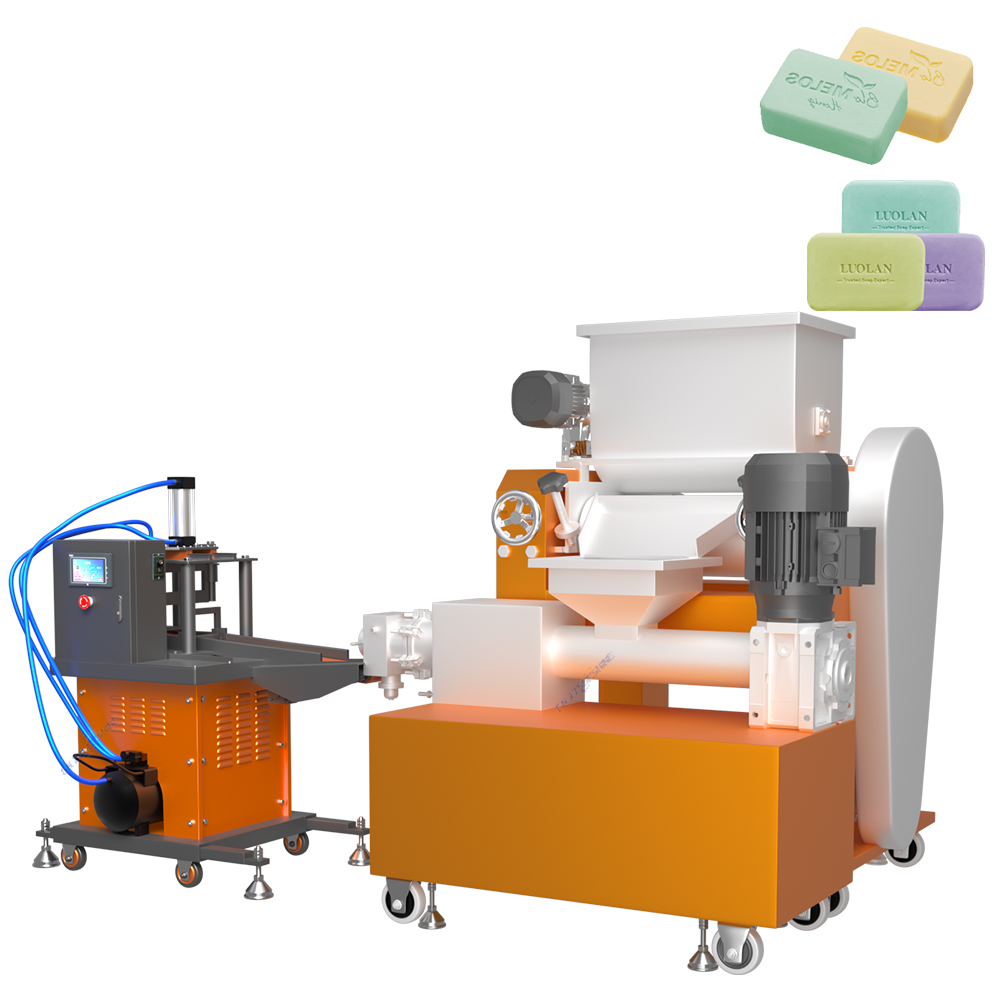

Integrating into Your Soap Making Production Line

This specialized soap mixer is the crucial first step in a successful soap making machine line. Once a perfectly saponified and homogenous soap paste is achieved in the mixing tank, it can be efficiently transferred downstream. Here, it might pass through refining equipment like an OEM three roller grinding mill to ensure smoothness, then into a soap plodder machine for bar soap (often a vacuum plodder to remove air and densify the mass), before being extruded, cut (using a custom soap cutting machine, pneumatic cutting machine, or electronic cutting machine), stamped with a soap stamping machine, and finally packaged, perhaps with a film packaging machine.

Whether you’re operating a large-scale automatic soap production line, a more compact mini soap production line, or focusing on specific segments like a beauty soap making line or washing liquid production equipment, the quality of your initial mix dictates the quality of your final product. Investing in a high-quality mixing machine specifically designed for handling liquid soap oils and caustic soda isn’t just an equipment purchase; it’s an investment in product excellence, production safety, and brand reputation. It ensures that the foundation of every bar or liquid soap leaving your facility is solid, consistent, and safe. Don’t let this critical step be your production line’s weakest link.