Okay, here is the article incorporating your requirements:

—

The Heart of Efficiency: Mastering Soap Mixing for Superior Production

For anyone serious about manufacturing soap – whether luxurious bath bars, robust laundry blocks, or versatile liquid formulations – the core process begins long before stamping or packaging. It starts in the mixing tank. Achieving the perfect blend of oils, fats, lye, and additives is paramount. This is where the chemical magic of saponification happens, transforming raw materials into soap base. The quality and consistency of this initial mix directly impact every stage that follows on your soap making production line.

That’s why selecting the right soap mixer is a critical investment. An efficient mixing machine ensures thorough homogenization, accelerates saponification, and guarantees a uniform batch every time. Whether you’re running a dedicated laundry soap making line, a high-end toilet soap finishing line, or a versatile operation producing both solid and liquid soap, the mixer sets the foundation.

Consider the Good Price Soap Making Machine Mixing Tank Soap Saponification Mixer Liquid Soap Mixing Tank. This isn’t just a container; it’s an engineered solution designed for performance and value. Built for durability and ease of cleaning, it tackles the demanding task of soap mixing effectively. Its robust construction handles viscous mixtures for bar soap production and equally manages the blending requirements of washing liquid production equipment.

However, the mixer is just one vital component. To truly streamline operations and maximize output, integrating it seamlessly with downstream equipment is key. After achieving the perfect saponified mix in the soap mixing tank, the material often moves to refining stages. Here, equipment like an OEM three roller grinding mill can further homogenize and smooth the soap paste.

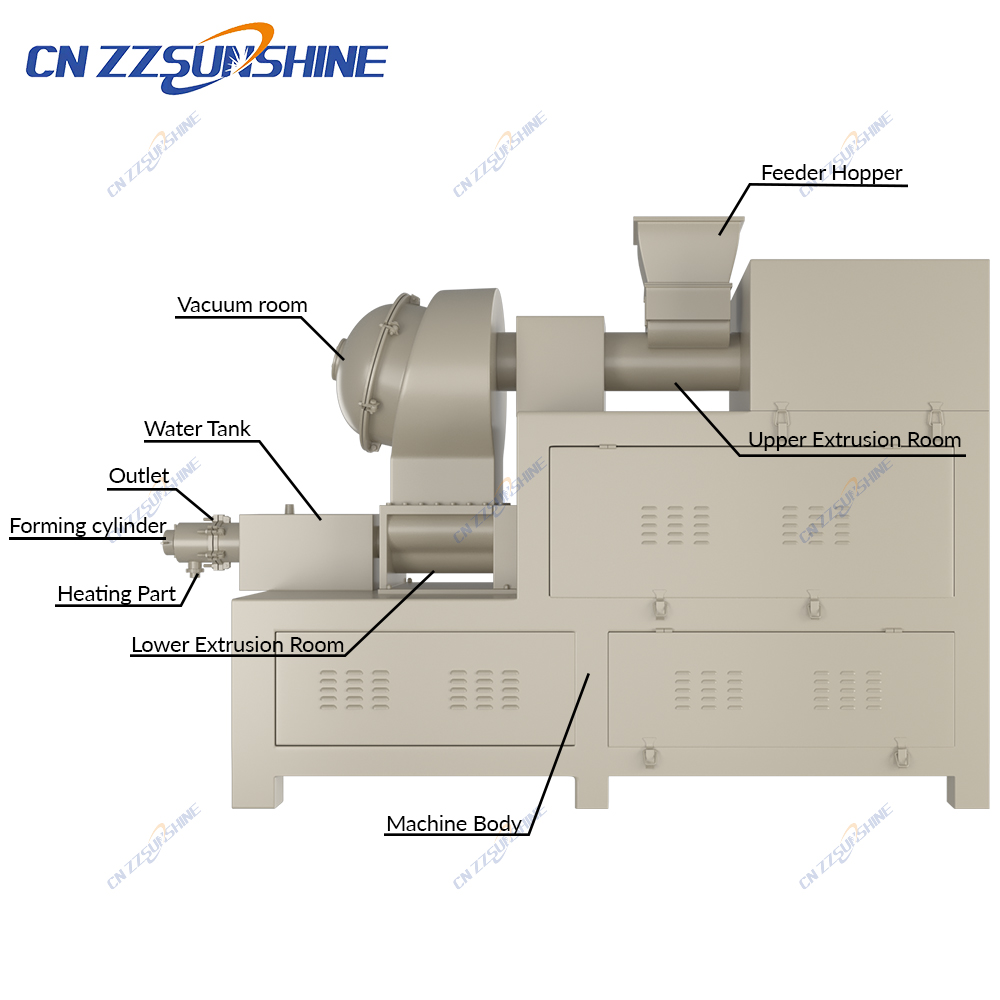

For solid soap production, the refined soap mass then typically proceeds to a soap plodder. A vacuum plodder is particularly effective, removing air pockets to create a dense, smooth extrusion ready for forming. This extrusion is then fed into cutting equipment – options range from manual cutting machines for smaller batches to high-speed automatic soap production lines featuring pneumatic cutting machines or electronic cutting machines. Precision soap cutting machines, such as an automatic block cutter machine or a custom soap cutting machine, ensure bars are sized consistently before drying and finishing.

The journey continues with soap stamping machines for branding and film packaging machines for wrapping, completing the bath soap making machine or laundry bar soap production line. Even mini soap production lines benefit from this logical progression, where a reliable soap mixer forms the indispensable starting point.

Ultimately, building an efficient soap making machine setup, whether a large-scale automatic soap production line or a smaller operation, hinges on understanding the synergy between components. Investing in a cost-effective, high-performing soap saponification mixer like the Good Price Soap Making Machine Mixing Tank ensures your foundational mixing process is robust. Pair it intelligently with the right soap plodder machine for bar soap, cutting solutions, and finishing equipment, and you lay the groundwork for consistent quality, increased productivity, and a thriving soap manufacturing business.

—