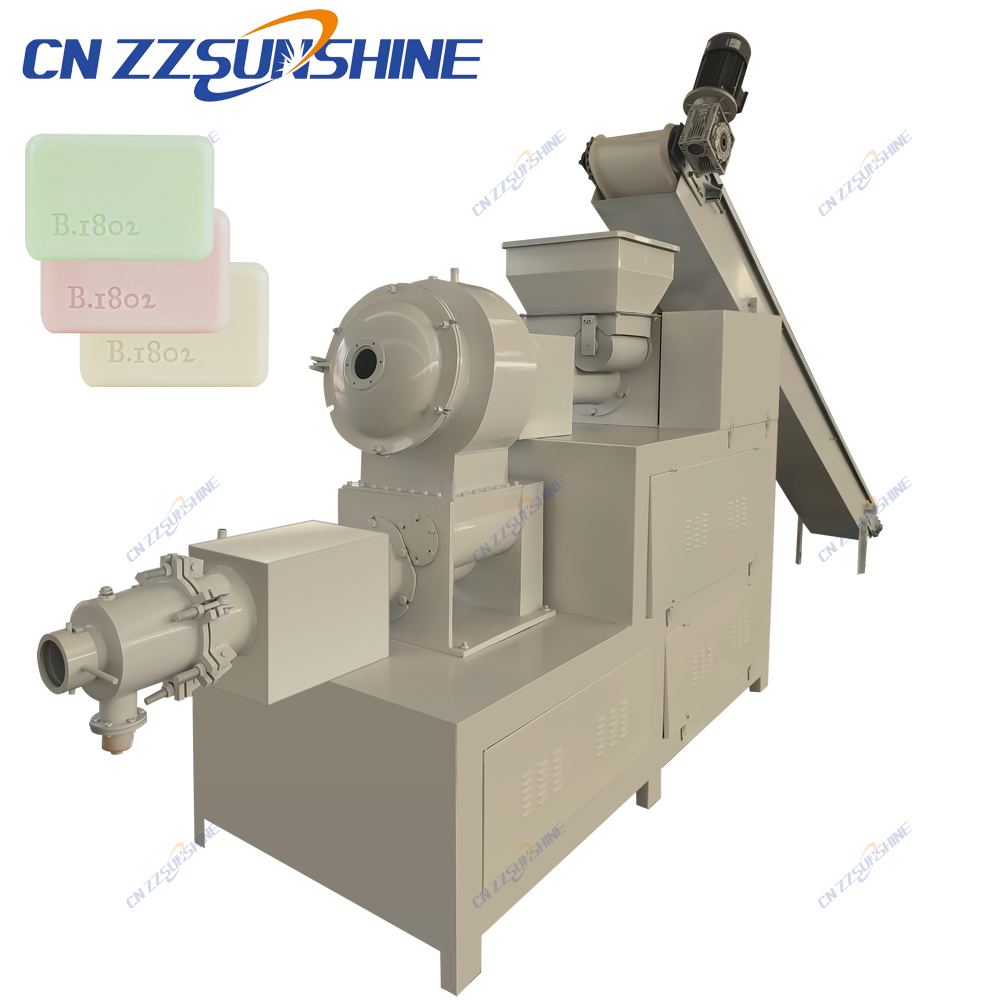

Excellent Quality First Soap Machine Line: Stainless Steel & Easy Operation for Laundry and Bath Soap Success

In today’s competitive soap manufacturing market, choosing the right equipment is paramount. For businesses focusing on laundry bar soap production or bath soap making, prioritizing excellent quality in your soap making production line is non-negotiable. This commitment starts with robust, hygienic construction and extends to efficient, user-friendly operation.

The cornerstone of a reliable soap making machine setup is the use of high-grade stainless steel. This material is essential for components like the soap plodder machine for bar soap, soap mixer, and three roller grinding mill. Stainless steel ensures durability, resists corrosion from harsh soap ingredients and cleaning agents, and meets stringent hygiene standards critical for producing both laundry soap and bath soap. It guarantees your final product is safe and maintains consistent excellent quality.

For manufacturers seeking flexibility, especially those starting out or producing specialized batches, a manual operate soap plant offers significant advantages. Combining core equipment such as a vacuum plodder for refining the soap base, a manual cutting machine or pneumatic cutting machine for precise sizing, and potentially a soap stamping machine for branding, this approach provides control without overwhelming complexity. The emphasis on easy install is crucial here. Well-designed manual operate soap plant components are engineered for straightforward setup, minimizing downtime and technical expertise requirements. This allows you to get your laundry bar soap production line or bath soap making machine operational quickly.

Whether you require a full automatic soap production line for high-volume output or a more hands-on semi-automatic system incorporating elements like a semi-automatic printer, the principle remains the same: excellent quality machinery forms the foundation. Key stages like mixing (utilizing a robust mixing machine), refining (with a reliable soap plodder), and cutting (employing a precise custom soap cutting machine or automatic block cutter machine) must be executed flawlessly to produce superior bars.

Investing in a well-designed soap making production line, built with premium stainless steel components and offering easy install features, particularly for manual operate soap plant configurations, empowers you to efficiently produce top-tier laundry soap and bath soap. This focus on quality equipment translates directly into a competitive product and a smoother manufacturing process. Discover how the right line can streamline your operations and enhance your soap quality today. Learn more about our tailor-made solutions for your specific production needs.