Crafting Excellence: The Complete Soap Production Line Explained

For businesses serious about scaling soap manufacturing – whether laundry bars, bath soaps, or specialty beauty products – investing in a comprehensive, integrated production line is paramount. Modern soap making production lines transform raw materials into finished, market-ready products efficiently and consistently. This journey begins with saponification and culminates in precisely formed bars.

The Foundation: Saponification and Soap Noodle Formation

The core process starts with the reaction between fats/oils (like palm oil) and caustic soda (sodium hydroxide) in a controlled saponification plant. This critical step produces the basic soap mass. For efficient large-scale production, this mass is then processed into soap noodles. A specialized soap noodle making machine handles this, often involving drying stages within a soap noodle dryer machine to achieve the optimal moisture content crucial for the next phases. This dried soap base, the noodle, is the fundamental building block.

Shaping the Bar: Refining and Forming

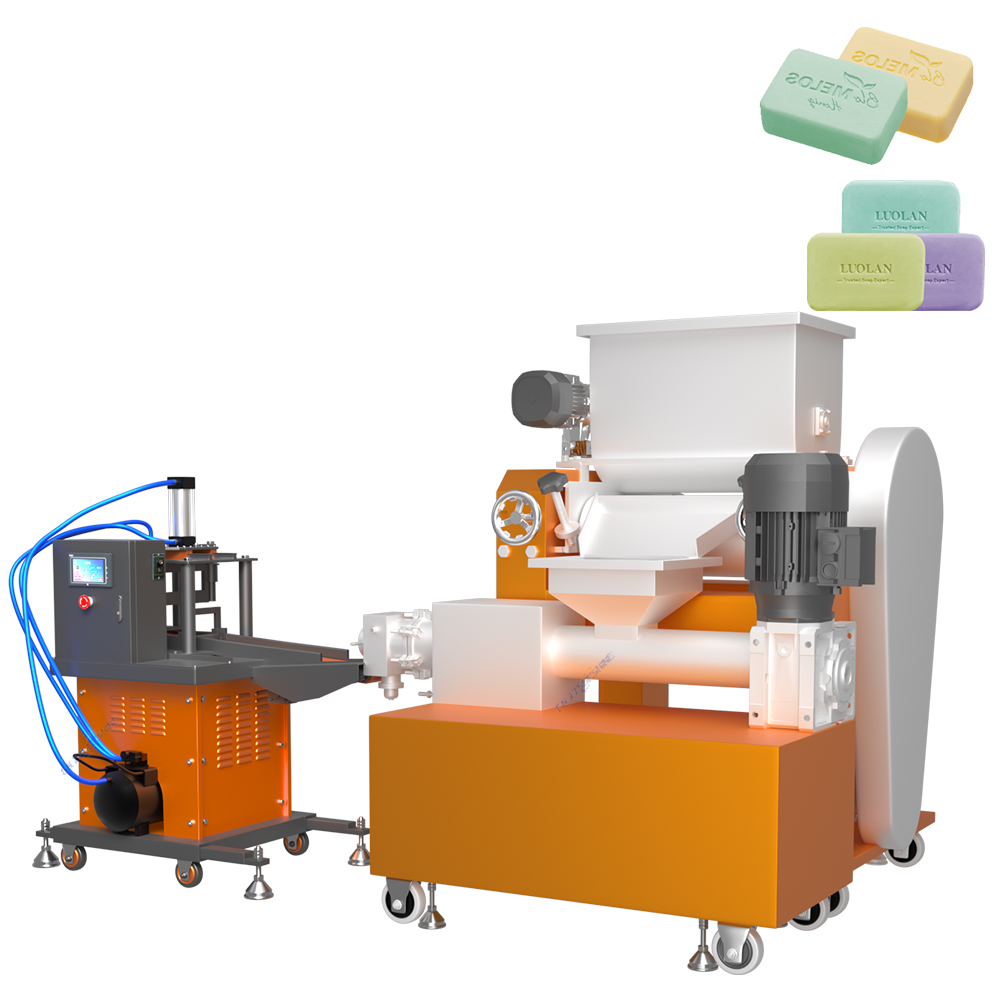

The dried soap noodles move to the refining stage. Here, a soap mixer or mixing machine blends in fragrances, colors, and other additives uniformly. The mixture is then fed into a soap plodder machine for bar soap, typically a vacuum plodder. This vital equipment compresses and extrudes the soap mass under vacuum, removing air pockets to ensure a dense, smooth bar texture. The continuous soap log exiting the plodder is then cut into individual blanks. An automatic block cutter machine or electric washing soap cutter performs this task swiftly and accurately, ensuring uniform bar sizes. Options like pneumatic cutting machines or electronic cutting machines offer further precision and automation levels. For bespoke needs, a custom soap cutting machine can be developed.

Finishing Touches: Stamping and Packaging

The cut soap blanks proceed to finishing. A soap stamping machine, potentially an automatic printer or semi-automatic printer, imprints the brand logo, product name, or other details onto each bar. Finally, a film packaging machine securely wraps the finished bars, preparing them for distribution. Whether you operate a dedicated laundry soap making line, a toilet soap finishing line, a laundry bar soap production line, or a beauty soap making line, these finishing stages are essential for product appeal and protection.

Why Choose an Integrated Line?

An automatic soap production line significantly boosts output, ensures consistent quality, minimizes manual handling, and reduces operational costs. From the initial saponification to the final packaged bar, each machine plays a crucial role. For smaller operations or specific applications, a mini soap production line offers a compact solution without compromising core functionality.

Partnering for Success

Investing in the right equipment is key. We offer expertise in designing and supplying tailored soap making machines, including OEM three roller grinding mills for specific refining needs and comprehensive solutions like washing liquid production equipment. Our focus is on providing reliable, efficient machinery to optimize your soap manufacturing process.

Ready to upgrade your soap production capabilities? Explore our range of integrated lines and specialized machinery designed for quality and efficiency. Contact us today to discuss your specific requirements.