The Long-Term Value of Compact Soap Production Lines: Efficiency Meets Affordability

For businesses looking to establish or expand their soap manufacturing capabilities, particularly in the laundry and bath soap segments, investing in a well-designed, mini soap production line offers significant long-term advantages. These compact systems deliver impressive efficiency, consistent quality, and remarkable versatility without the hefty price tag or spatial demands of larger, fully automatic soap production line setups. They represent a smart entry point or scaling solution, especially when focusing on producing high-demand items like soap noodle or finished bars.

At the heart of any effective soap making production line, regardless of scale, lies the mixing process. A robust soap mixer or mixing machine is crucial for creating a homogeneous blend of fats, oils, alkali, and additives. For smaller operations, a well-engineered mixer ensures thorough incorporation of ingredients, forming the essential soap noodle base that feeds downstream processes. This foundational step directly impacts the quality and consistency of the final bar – whether it’s a rugged laundry bar soap or a luxurious bath soap.

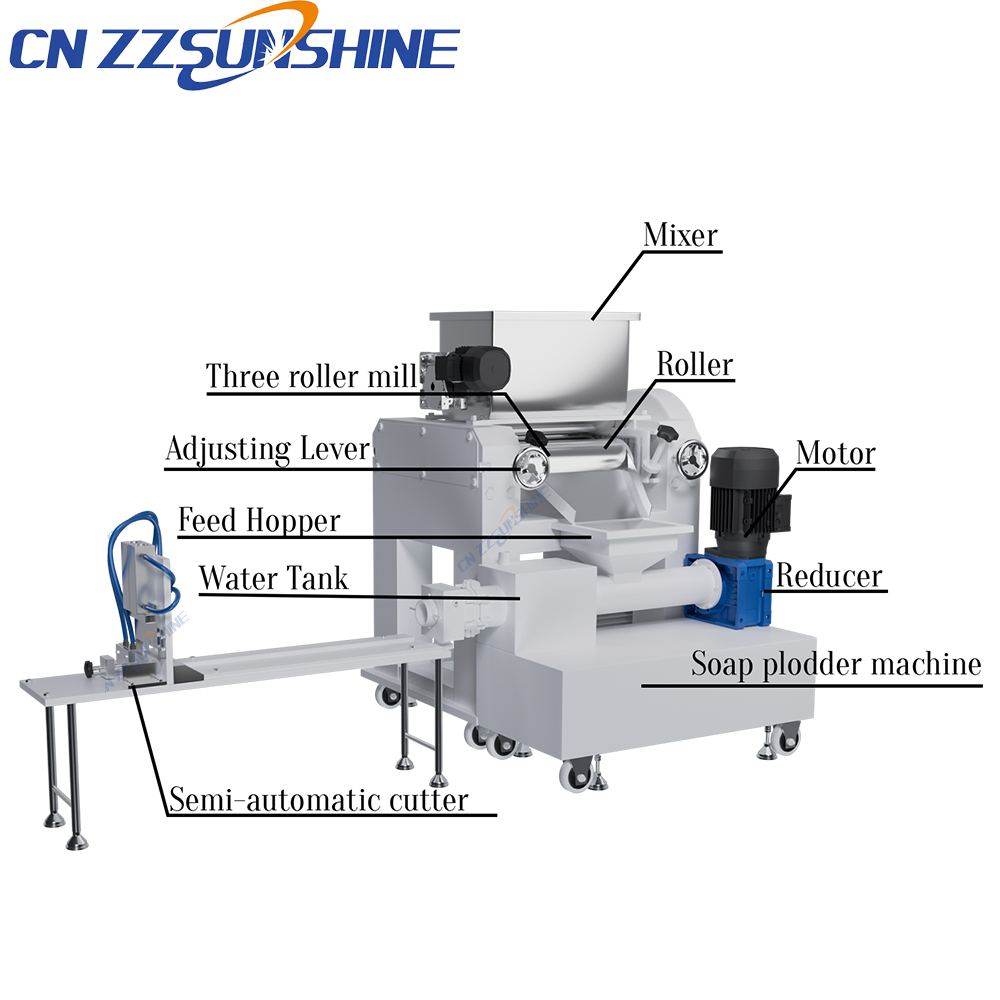

Following mixing, refining the soap mass is often necessary to achieve the desired texture and performance. This is where equipment like an OEM three roller grinding mill proves invaluable. These mills work the soap through multiple rollers, smoothing out the texture and ensuring uniformity. While some mini soap production lines might integrate a compact grinder, others, especially those focused on laundry soap making line where a slightly coarser texture might be acceptable, might streamline the process.

The next critical stage involves extrusion and forming. A soap plodder machine for bar soap, often a vacuum plodder even in smaller configurations, compacts the mixed soap, removes air pockets (critical for a harder, longer-lasting bar), and extrudes a continuous log of soap. The vacuum plodder is particularly important for producing dense, high-quality bars suitable for both toilet soap finishing line and laundry bar soap production line applications. The extruded log is then ready for cutting.

Precision cutting is vital for product uniformity and presentation. Options range from manual cutting machine setups suitable for very low volumes to more efficient electric washing soap cutter or pneumatic cutting machine units. An automatic block cutter machine represents a significant efficiency boost within a mini soap production line, automating the log cutting into individual bar-sized blocks with consistent dimensions and minimal waste. Whether it’s a custom soap cutting machine or a standard model, reliable cutting ensures professional-looking products.

While a semi-automatic printer might suffice for smaller batches or specific beauty soap making line products, integrating an automatic printer significantly increases output for high-volume staples like laundry soap. Finally, wrapping protects the product and enhances brand appeal. A simple yet reliable film packaging machine is often sufficient for laundry bar soap production, while bath soaps might require more sophisticated wrapping solutions.

The true benefit of investing in a dedicated soap making machine setup, even a mini soap production line, lies in its focused efficiency and cost-effectiveness. By selecting the right combination of equipment – a capable soap mixer, potentially a mill, a soap plodder, an efficient cutter (automatic block cutter machine, electric washing soap cutter, etc.), and appropriate finishing equipment – manufacturers can produce high volumes of consistent quality soap noodle or finished bars. This approach is ideal for businesses targeting markets with good price laundry soap demands or seeking to establish a niche in bath soaps, offering a reliable pathway to profitability and sustainable growth.