Building Resilience: The Backbone of Hotel-Grade Laundry Soap Production

For hotel chains and large-scale hospitality providers, the demand for consistent, high-quality laundry soap is constant. Maintaining this supply requires robust, reliable manufacturing capabilities. Investing in a durable hotel laundry soap production line isn’t just about output; it’s about ensuring operational continuity, product integrity, and long-term cost efficiency. The right equipment forms the foundation of a successful, sustainable supply chain.

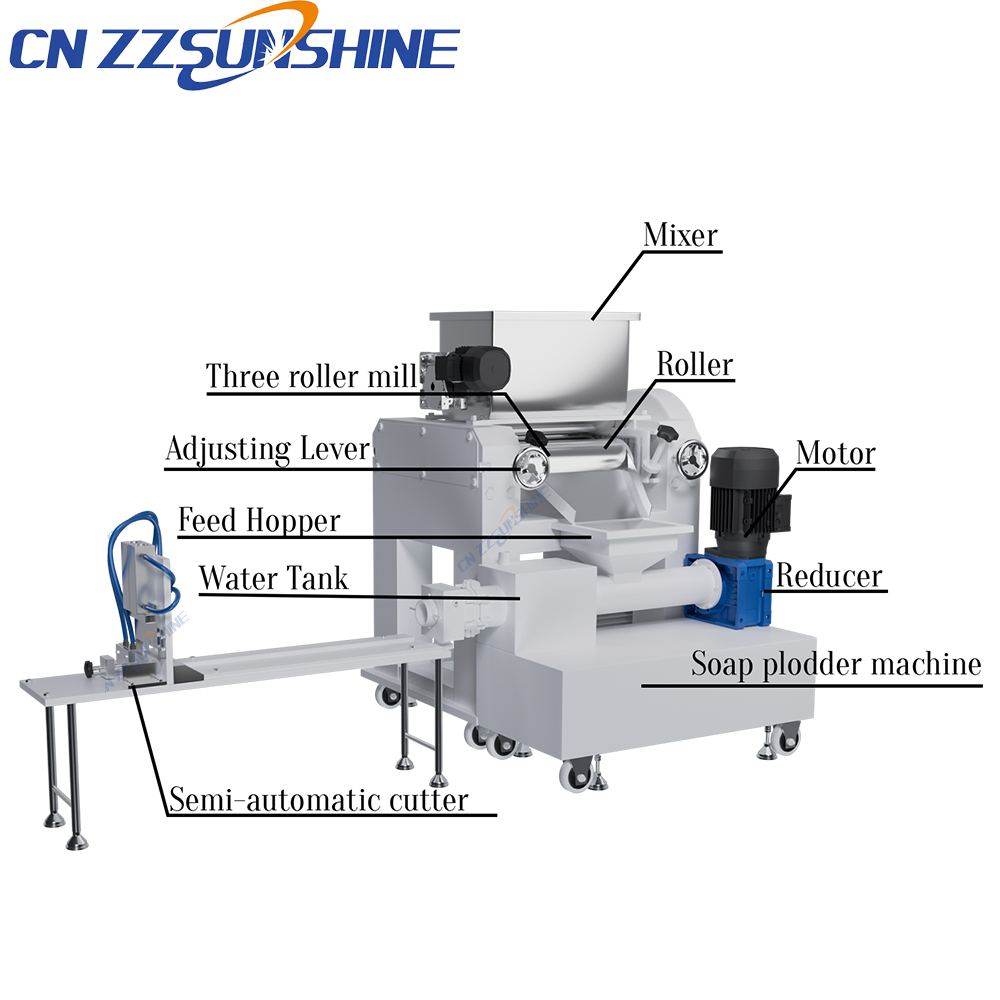

At the heart of any efficient laundry bar soap production line lies precision and reliability. The journey begins with raw material preparation. A stainless steel small mixer machine is crucial here. Constructed from high-grade, corrosion-resistant stainless steel, this mixing machine ensures uniform blending of fats, oils, alkalis, and additives. Its durability guarantees hygiene, prevents contamination, and withstands the rigors of daily industrial use, critical for producing the consistent base needed for effective hotel laundry bars.

Once mixed, the soap mass undergoes refining to achieve the desired texture and homogeneity. This is where a robust soap plodder machine for bar soap, often a vacuum plodder, comes into play. This stage removes air pockets, compacts the soap, and ensures a smooth, dense bar. A high-quality plodder is vital for producing laundry soap that lathers well, cleans effectively, and doesn’t crumble prematurely – essential qualities demanded by the hospitality industry.

The refined soap log then moves to forming and cutting. An efficient laundry soap forming making machine shapes the continuous log into the desired bar size. Following this, precision cutting is paramount. An automatic block cutter machine or electric washing soap cutter ensures uniform bar dimensions with clean, sharp edges. Options range from manual cutting machines for smaller setups to fully automatic soap cutter systems integrated into larger automatic soap production lines. The choice depends on scale, but durability in the cutting mechanism guarantees consistent results batch after batch.

For hotels requiring branded bars, finishing touches are key. Soap stamping machines or semi-automatic printers impart logos or information onto each bar. Finally, efficient wrapping is handled by a reliable film packaging machine, protecting the soap until use. For operations also supplying guest amenities or expanding their product range, integrating a beauty soap making line or toilet soap finishing line alongside the main laundry soap making line can be a strategic move, leveraging shared infrastructure.

Choosing the right equipment partners is critical. Look for manufacturers offering custom soap cutting machine solutions or OEM capabilities to tailor machinery to specific throughput needs or bar specifications. Whether investing in a comprehensive automatic soap production line or a more compact mini soap production line, prioritizing build quality – like stainless steel construction for critical components – minimizes downtime and maintenance costs.

Ultimately, a durable hotel laundry soap production line, encompassing essential components like the stainless steel small mixer machine and the laundry soap forming making machine, is an investment in operational resilience. It ensures hotels can reliably produce high-performing laundry soap that meets guest expectations, maintains brand standards, and supports efficient in-house laundry operations for years to come. Selecting robust, well-engineered soap making machinery is the cornerstone of building this essential supply chain capability.