Beyond the Basics: Elevating Your Soap Production with Versatile Machinery

The quest for high-quality, cost-effective soap production demands more than just basic equipment. Whether you’re crafting specialty green laundry soap, formulating luxurious bath bars, or requiring precision grinding, having the right machinery is paramount. Modern soap making production lines offer tailored solutions for diverse needs.

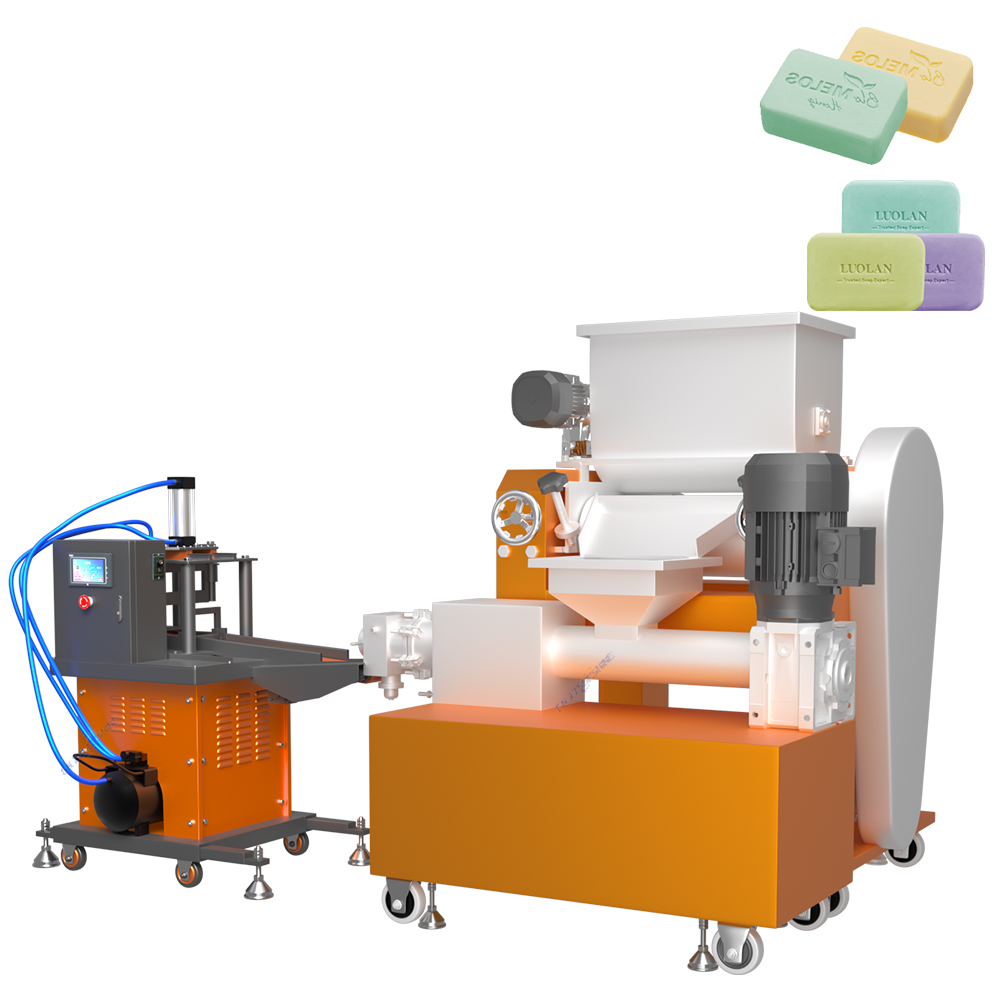

For robust laundry bar soap production lines, efficiency starts at the core. A dedicated soap plodder machine for bar soap, particularly a Vacuum plodder, is essential. It processes mixed soap base into a continuous, homogenous extrusion, crucial for forming high-density bars ready for cutting. Pair this with an automatic block cutter machine or a pneumatic cutting machine to ensure consistent sizing and minimal waste, significantly boosting your line’s output.

Creating appealing bath soap or beauty soap often involves refined texture and aesthetics. Here, a professional three roller mill plant (or OEM three roller grinding mill) becomes indispensable. These mills refine the soap base, ensuring a smooth, lump-free paste ideal for stamping and packaging. Integrating equipment like an automatic soap stamping machine and a reliable film packaging machine completes your toilet soap finishing line, delivering products that look as good as they function.

For smaller operations or specialized batches, mini soap production line options exist, often incorporating semi-automatic or manual cutting machine components alongside compact soap mixer and plodder units. The key is selecting machinery – be it a custom soap cutting machine, an electric washing soap cutter, or a soap plodder extrude making machine – that aligns precisely with your production volume, soap type, and quality goals. Investing in the right soap making machine technology is the cornerstone of a successful, adaptable manufacturing operation.