Crafting Superior Soap: The Essential Machinery Behind Every Bar

The journey from raw materials to a beautifully finished bar of soap hinges on sophisticated machinery. Whether producing robust laundry bars or luxurious bath soaps, selecting the right equipment is paramount for efficiency, quality, and scalability. Modern soap making production lines integrate specialized machines designed for each critical stage, ensuring consistent results and meeting diverse market demands.

For manufacturers prioritizing sustainability, equipment like the Green Plant Used Soap Making Machine offers an eco-conscious solution. These machines, often built with energy-efficient components and designed for minimal waste, cater to brands focused on reducing their environmental footprint without compromising on output. This aligns perfectly with the growing consumer demand for greener manufacturing practices across the laundry bar soap production line and toilet soap finishing line sectors.

Central to any laundry soap making line is the reliable Sanitary Laundry Soap Noodle Making Machine. This equipment is engineered to handle the specific formulations and higher volumes typical of laundry products, producing uniform soap noodles – the base material for subsequent processing. Hygiene is critical here, and these machines are constructed with materials and designs that facilitate easy cleaning and maintain sanitary conditions throughout production.

Achieving the perfect soap base requires thorough mixing. The Stainless Steel Soap Noodles Mixing Machine is indispensable. Constructed from durable, non-reactive stainless steel, this soap mixer ensures homogeneous blending of soap noodles, fragrances, colors, and additives. Its robust design guarantees longevity and prevents contamination, crucial for maintaining product integrity in both bath soap making machine setups and high-volume laundry soap making line operations.

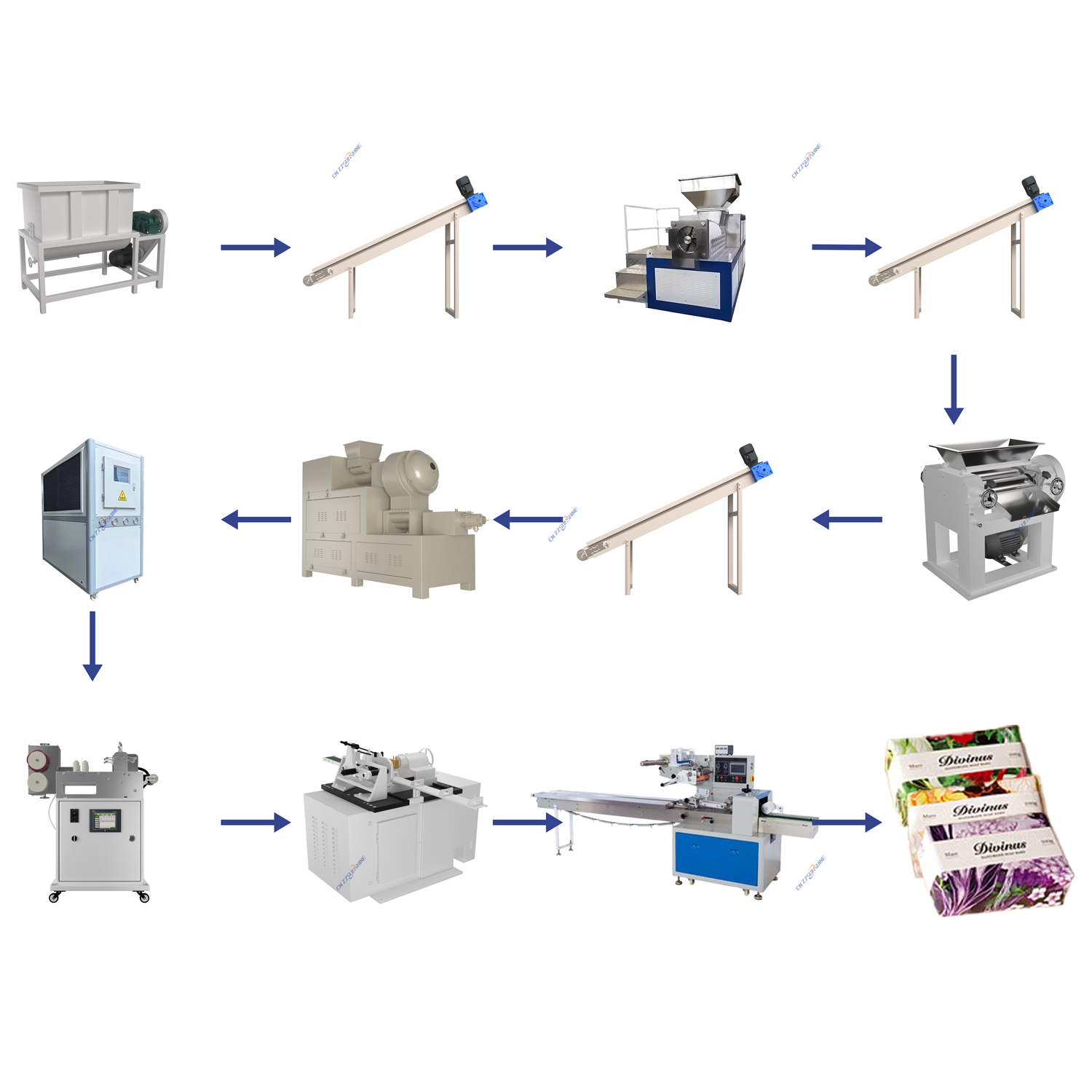

Beyond mixing, a complete automatic soap production line incorporates several key components. A high-performance soap plodder, particularly a vacuum plodder, removes air pockets for a denser, smoother bar. Precision cutting follows, utilizing automatic block cutter machines or advanced electronic cutting machines for consistent sizing. Finally, soap stamping machines and film packaging machines add branding and protection.

From compact mini soap production line solutions for startups to fully automatic soap production line for large factories, investing in the right soap making machine technology – including reliable mixing machines, efficient plodders, and precise cutters – is the foundation for producing high-quality, market-ready soap products efficiently and reliably. Partnering with experienced manufacturers offering custom soap cutting machine and OEM three roller grinding mill options ensures your equipment perfectly matches your specific production goals.