The Engine Behind Your Suds: Demystifying Modern Soap Production Lines

In today’s competitive market, soap manufacturers face a dual challenge: delivering high-quality products consumers love while maintaining efficient, cost-effective, and increasingly sustainable operations. Whether crafting luxurious bath bars, robust laundry soaps, or specialized beauty soaps, the backbone of consistent, scalable production lies in the machinery. Understanding the core components of a soap making production line is key to unlocking efficiency and meeting diverse market demands.

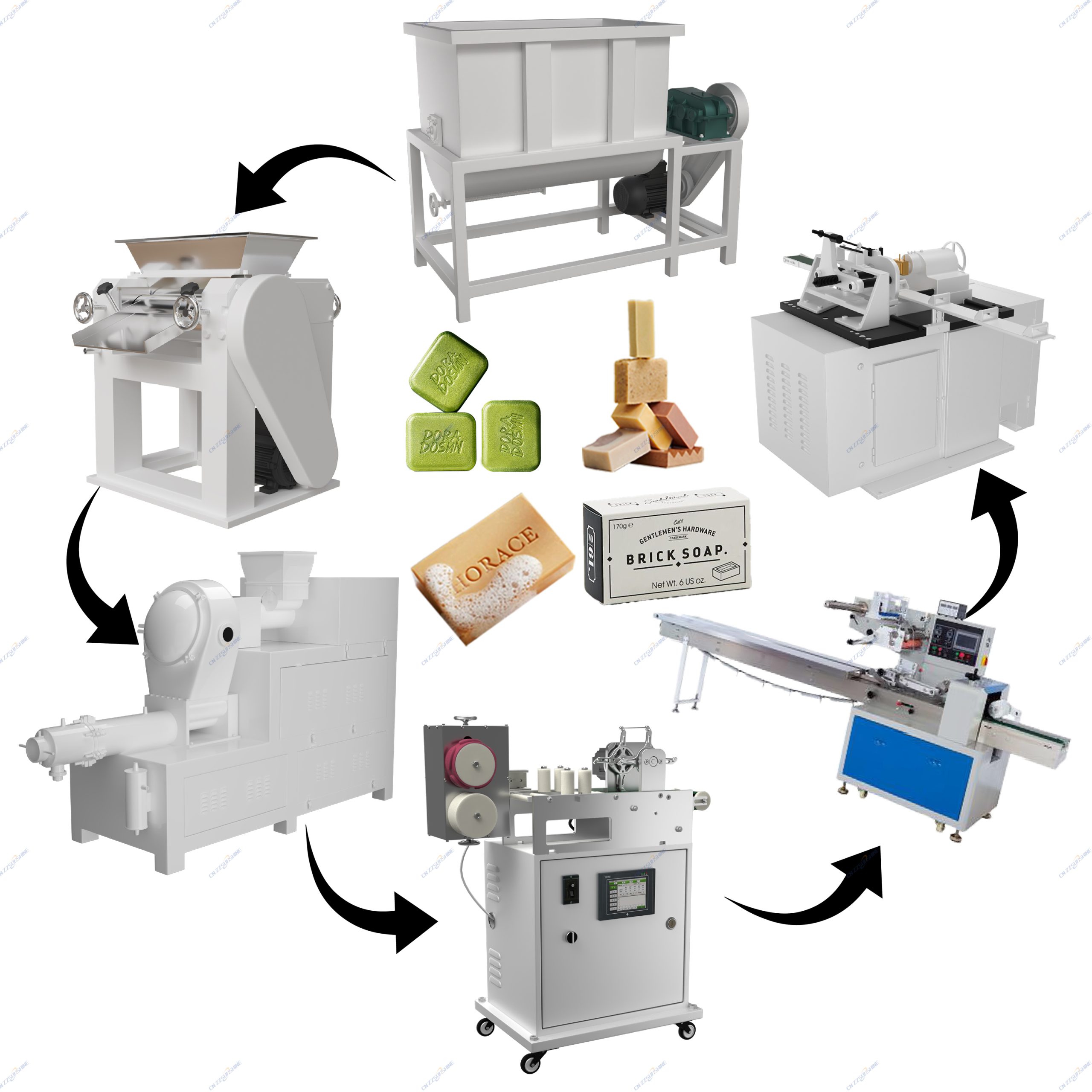

Gone are the days of purely manual processes dominating large-scale manufacturing. Modern soap making machines form integrated systems designed for precision and throughput. The journey begins with mixing. A robust soap mixer or mixing machine is crucial for thoroughly blending fats, oils, lye, fragrances, and additives into a homogenous mass. This foundational step ensures consistent quality and performance in every bar.

For bar soaps – encompassing laundry bars, bath bars, and toilet soaps – the mixed soap base undergoes refining and forming. Enter the soap plodder, a workhorse in any laundry soap making line or toilet soap finishing line. This machine compresses the soap mixture, removing air pockets and creating a dense, uniform extruded log. Vacuum plodder variants enhance this process by working under reduced pressure, yielding an even smoother, denser bar with superior lather and longevity.

The extruded soap log then moves to cutting. This is where precision is paramount. Automatic block cutter machines or sophisticated custom soap cutting machines slice the log into precise, uniform billets or blocks. Options range from electric washing soap cutters for high-volume lines to pneumatic cutting machines and electronic cutting machines offering varying degrees of automation and precision. Even manual cutting machines serve a purpose in smaller setups or specialized applications.

The cut soap pieces then progress to finishing. For bath and beauty soaps, a three roller grinding mill (often available as OEM three roller grinding mill) might be employed for super-refining, creating a silky texture. Stamping imparts brand identity and shape using an efficient soap stamping machine. Finally, packaging protects the product and attracts consumers. Film packaging machines provide secure, hygienic wrapping suitable for various retail environments.

The beauty of modern soap production lines lies in their scalability and flexibility. A comprehensive automatic soap production line integrates mixing, plodding, cutting, stamping, and packaging into a seamless, high-throughput system, ideal for large-scale manufacturers. Conversely, a mini soap production line or semi-automatic setups, featuring components like a semi-automatic printer or manual cutting machine, offer a cost-effective entry point for smaller businesses or those producing niche products. For liquid products, dedicated washing liquid production equipment follows different, specialized processes.

Investing in the right machinery – whether it’s a core soap plodder machine for bar soap, an efficient cutter, or a complete bath soap making machine solution – is an investment in quality, efficiency, and sustainability. By understanding the roles of these machines within a laundry bar soap production line or a beauty soap making line, manufacturers can optimize their operations, reduce waste, and consistently deliver the superior suds that customers expect. Choosing adaptable equipment paves the way for growth and success in the ever-evolving soap industry.