Building Your Bar Soap Dream: Smart Machinery for Small Factories

For entrepreneurs and small manufacturers eyeing the lucrative bar soap market – encompassing laundry, bath, and toilet soaps – the journey begins with the right production equipment. Finding a reliable, cost-effective soap making production line that delivers good quality without breaking the bank is paramount. This is where understanding the core machinery and its capabilities for outputs like 100-150kg/h becomes crucial for establishing a profitable small factory.

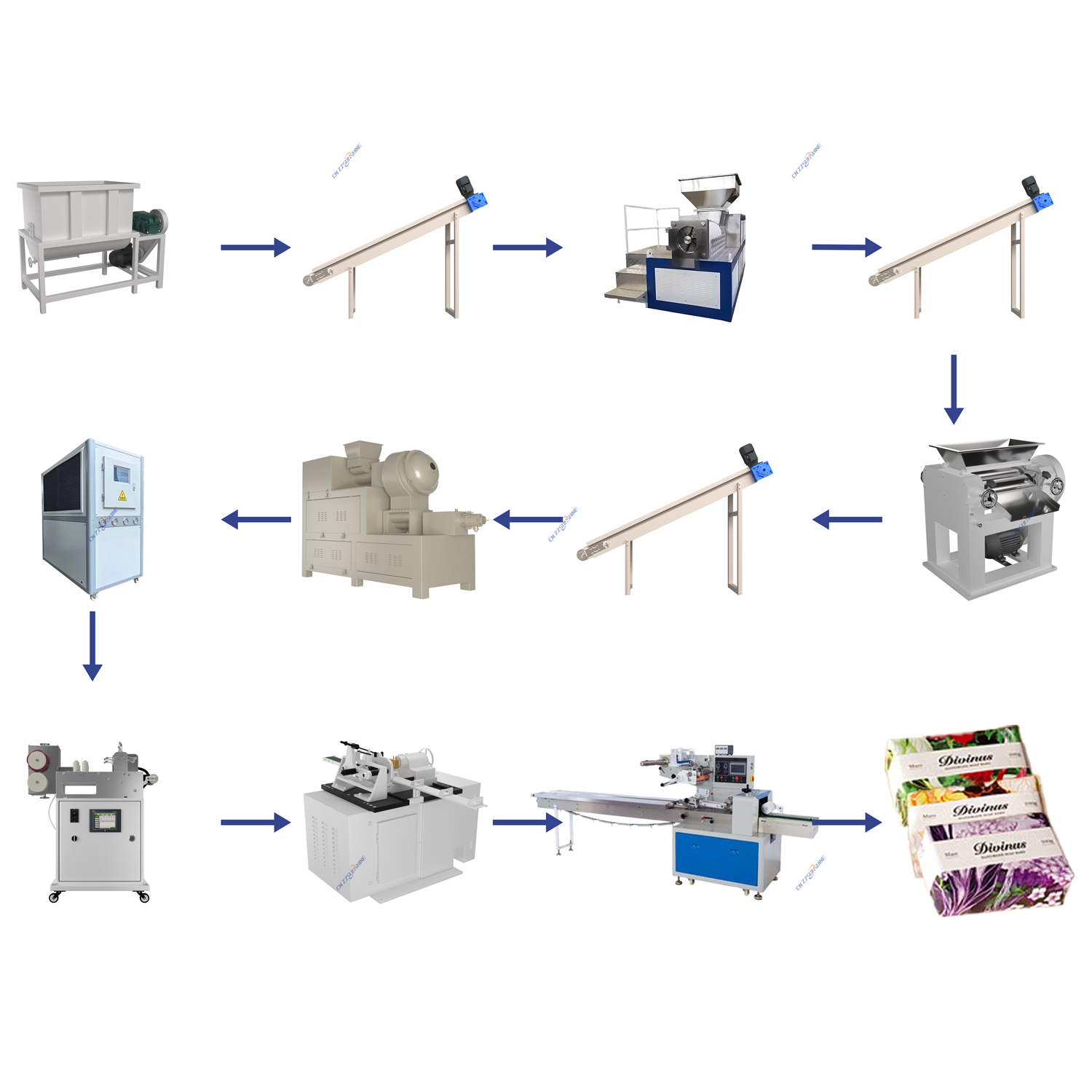

A compact yet efficient automatic soap production line for bar soaps typically revolves around several key machines designed for streamlined operation. The process often starts with a robust soap mixer or mixing machine, where raw materials (fats, oils, alkalis, additives) are blended into a homogenous paste. For higher quality and smoother texture, especially in toilet soap finishing line or bath soap making machine setups, this mixture may pass through an OEM three roller grinding mill for refining.

The heart of shaping the bar lies in the soap plodder machine for bar soap. A vacuum plodder is particularly valuable as it removes air pockets during extrusion, resulting in a denser, longer-lasting bar with a finer finish – essential for premium beauty soap making line products. The plodder extrudes a continuous log of soap, which then needs precise sizing.

This is where cutting technology comes in. An automatic block cutter machine slices the log into uniform billets or blocks. Options range from pneumatic cutting machines to electronic cutting machines, offering varying degrees of automation and precision. While a manual cutting machine might suffice for very low-volume startups, an automatic soap production line significantly boosts efficiency and consistency at outputs like 100-150kg/h.

Following cutting, the soap billets often proceed to stamping and branding. An automatic printer or semi-automatic printer (depending on the desired level of automation and budget) imprints logos and information onto the soap bars. Finally, packaging is handled by equipment like a film packaging machine, ensuring the finished product is protected and presented professionally.

For factories focused specifically on laundry soap making line or laundry bar soap production line, the emphasis might lean towards robust mixing and efficient plodding and cutting, potentially with slightly less focus on the ultra-refining stages needed for toilet soaps. However, the core principles of quality machinery remain.

The appeal of a mini soap production line configured for 100-150kg/h output is clear for small factories: manageable space requirements, lower initial investment compared to large-scale lines, and the flexibility to produce various bar types (laundry, bath, toilet). This setup allows manufacturers to enter the market or scale up existing operations effectively. When sourcing equipment, look for suppliers offering custom soap cutting machine options or the ability to tailor the line (OEM) to your specific soap type and factory layout.

Investing in a well-designed soap making machine line, incorporating reliable components like a quality soap plodder, efficient cutter, and appropriate finishing equipment, is the foundation for producing good quality bar soaps consistently. By targeting machinery capable of 100-150kg/h, small factories can achieve a competitive small factory price point while building a reputation for solid, dependable products in the laundry, bath, and toilet soap sectors. Careful selection ensures your production line is an asset, driving growth and profitability from the first bar. Get your tailored quote today!