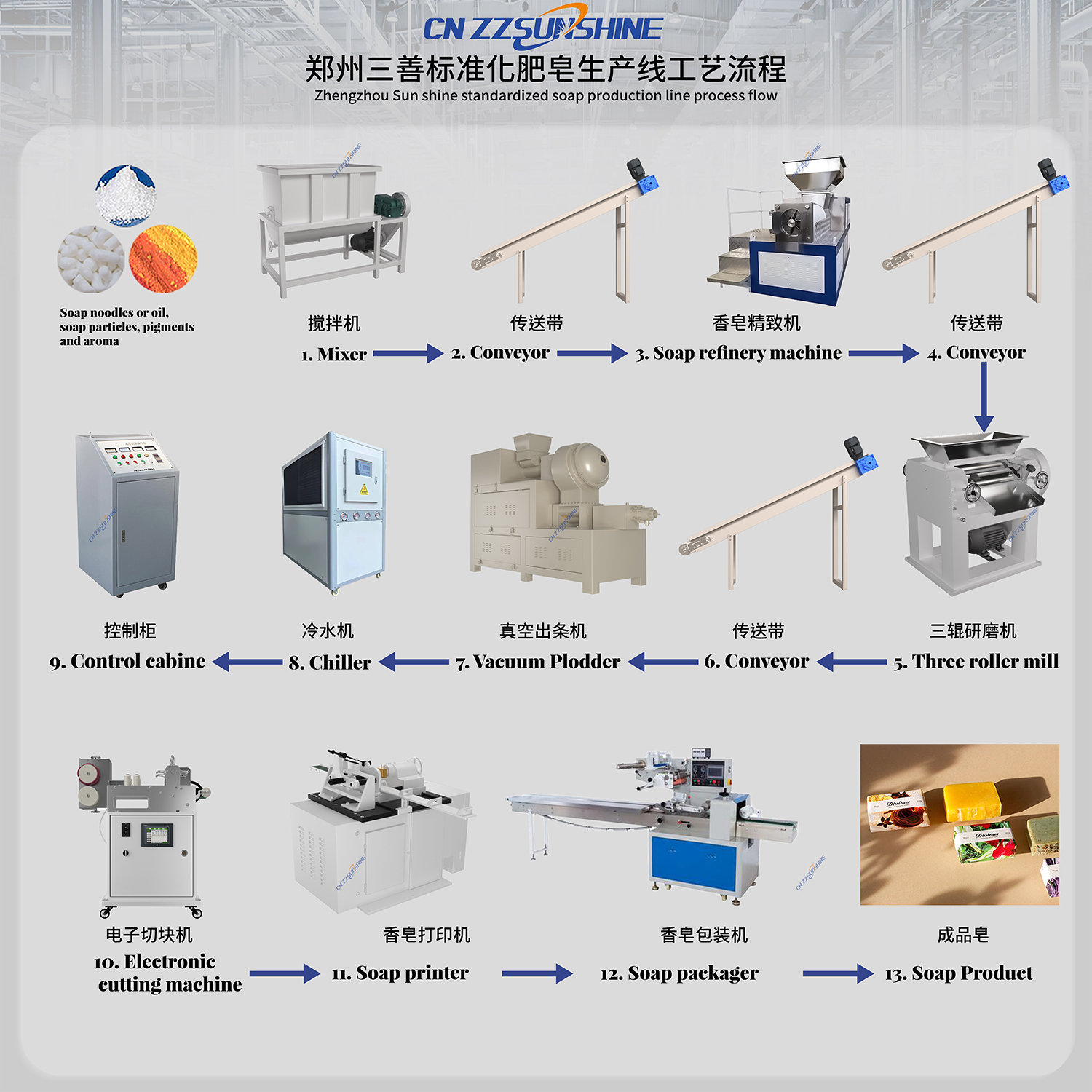

Implementing an automatic soap production line revolutionizes bar soap manufacturing, significantly boosting output and consistency while reducing labor costs. This integrated system efficiently handles the entire process from raw material mixing to finished bar packaging, essential for both laundry soap making lines and toilet soap finishing lines.

The core begins with a robust industrial mixer for chemical processing, precisely combining fats, oils, lye, and additives. Consistent mixing is critical for quality. This homogeneous soap base is then fed into a specialized soap plodder machine for bar soap. Modern lines often utilize a vacuum plodder, which removes trapped air under pressure. This key step prevents bubbles, ensuring a denser, longer-lasting bar with a smooth texture – vital for premium bath soap making machines and beauty soap making lines.

Following extrusion, the continuous soap log enters the cutting stage. An automatic block cutter machine or an electric washing soap cutter delivers precise, uniform bars at high speed, minimizing waste. For bespoke shapes or sizes, a custom soap cutting machine can be integrated. Finally, an automatic packing machine for food-grade materials efficiently wraps and packages the finished bars for distribution.

The advantages are clear: higher throughput, reduced manual handling, and superior product uniformity. Whether establishing a new laundry bar soap production line or upgrading an existing toilet soap finishing line, automation is key to competitive manufacturing. Choosing reliable components like a high-performance soap mixer and vacuum plodder directly impacts the quality and efficiency of the final product. Partnering with experienced suppliers ensures optimal integration and operation of your complete soap making production line.