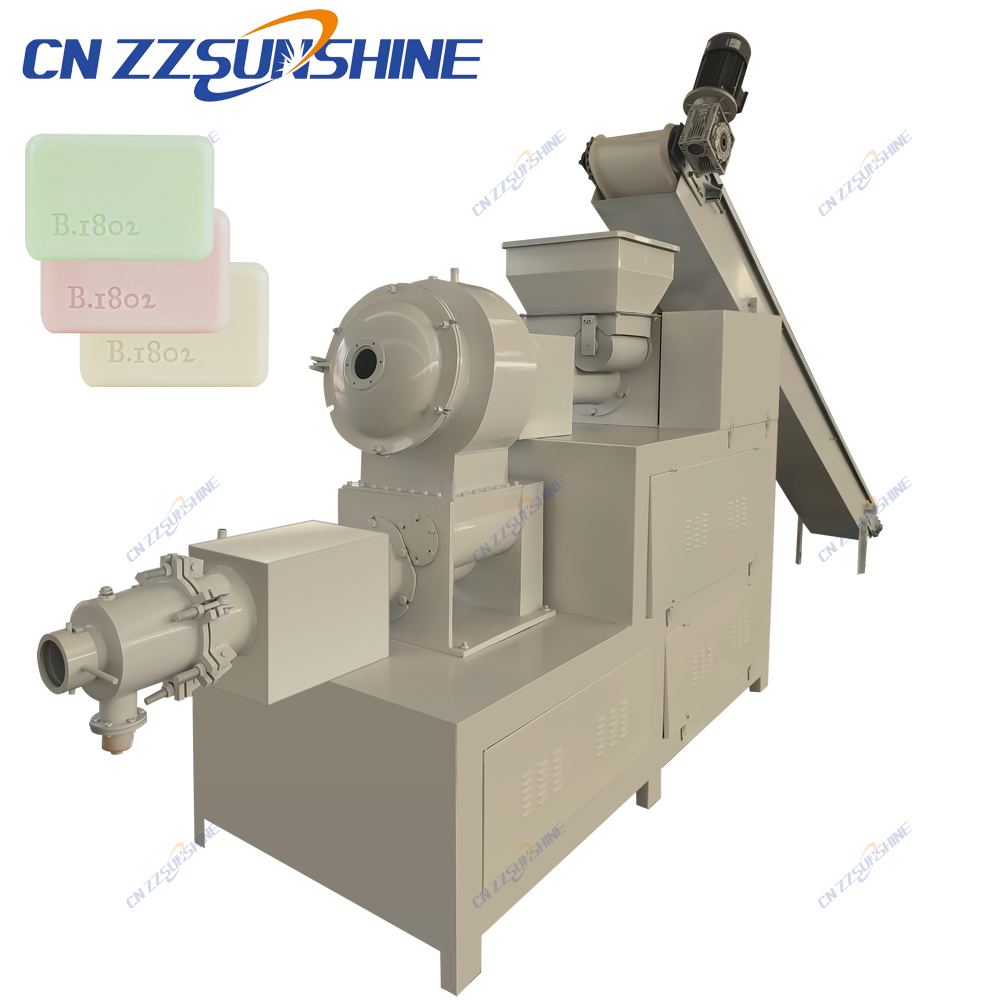

In today’s competitive industrial landscape, a well-designed soap making production line is essential for achieving high efficiency and consistent quality in bar soap manufacturing. This integrated system typically includes key components like a vacuum plodder for homogenizing the soap base, an industrial mixer for chemical processing to blend fragrances and additives uniformly, and an automatic soap cutting machine for precise sizing. By incorporating a vacuum plodder, manufacturers can eliminate air bubbles, resulting in denser, longer-lasting bars that meet stringent hygiene standards. For instance, in a laundry bar soap production line, the use of a high-performance soap mixer ensures even distribution of cleansing agents, while an electric washing soap cutter automates slicing to reduce labor costs and minimize waste.

Moreover, modern soap making machines often feature customizable options, such as a custom soap cutting machine tailored to specific bar dimensions or an industrial chiller for machinery that maintains optimal temperatures during extrusion, preventing overheating and extending equipment lifespan. This is particularly beneficial in bath soap making machines where delicate ingredients require gentle handling. The integration of an automatic soap production line not only boosts throughput—handling up to several tons per day—but also enhances safety by reducing manual intervention in chemical mixing processes.

For businesses seeking cost-effective solutions, adopting a complete toilet soap finishing line can streamline operations from mixing to packaging, offering scalability for small to large factories. Key advantages include improved product consistency, reduced energy consumption, and faster time-to-market, making it ideal for OEM three roller grinding mill applications in cosmetics. Ultimately, investing in a reliable soap plodder machine for bar soap ensures sustainable growth, as it supports eco-friendly practices by minimizing material loss and optimizing resource use. With advancements like these, manufacturers can easily upgrade their setups to meet global demand for high-quality personal care products.