In today’s competitive personal care market, achieving consistent quality and high output demands sophisticated equipment. An integrated automatic soap production line is no longer a luxury but a necessity for manufacturers aiming for scale and profitability. This streamlined system seamlessly connects critical processes, minimizing manual handling and maximizing efficiency.

The heart of any robust laundry bar soap production line or toilet soap finishing line lies in its core processing units. It begins with a high-shear industrial mixer for chemical processing, ensuring thorough blending of fats, oils, lye, and additives into a homogenous paste. This precision mixing machine is crucial for achieving the desired saponification and final bar properties.

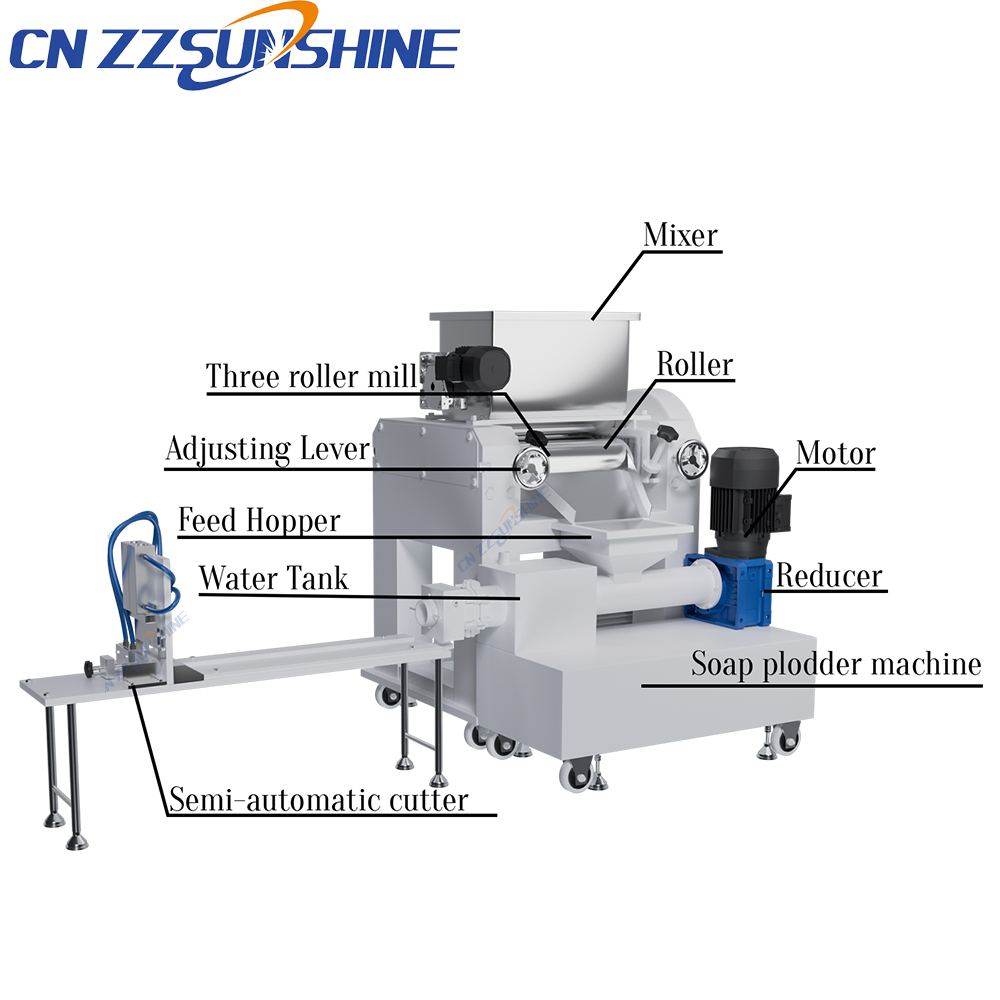

Following mixing, the soap base moves to the refining stage. Here, a high-performance soap plodder machine for bar soap, often a dual-stage vacuum plodder, takes center stage. This equipment compresses the soap, removes air pockets (critical for preventing crumbling), and delivers a dense, continuous noodle or extruded bar. The vacuum plodder stage is essential for producing a bar with consistent density and texture, whether for laundry or bath applications.

Next, the continuous soap log enters the forming and finishing section. A custom soap cutting machine, frequently an electric washing soap cutter for precise, hygienic sizing, slices the extruded log into individual bar blanks. For bath soap making machines or beauty soap making lines, additional finishing like milling (potentially using a specialized three roller mill for cosmetics-grade additives), stamping, embossing, and polishing might be integrated within the toilet soap finishing line. Finally, an automatic packing machine for food-grade or cosmetic packaging ensures swift, sanitary wrapping and boxing of the finished bars.

Investing in a well-engineered automatic soap production line, sourced from a reliable manufacturer, offers undeniable advantages. These include significant labor reduction, minimized raw material waste, enhanced product consistency, improved hygiene control, and the ability to scale production rapidly. Key components like the vacuum plodder for consistent density, the dual stage extruder for final bar formation, and the high-speed electric soap cutter directly impact throughput and product quality. Whether setting up a new laundry bar soap production line or upgrading an existing bath soap making machine operation, integrating these technologies is pivotal for sustainable growth in the global soap industry.