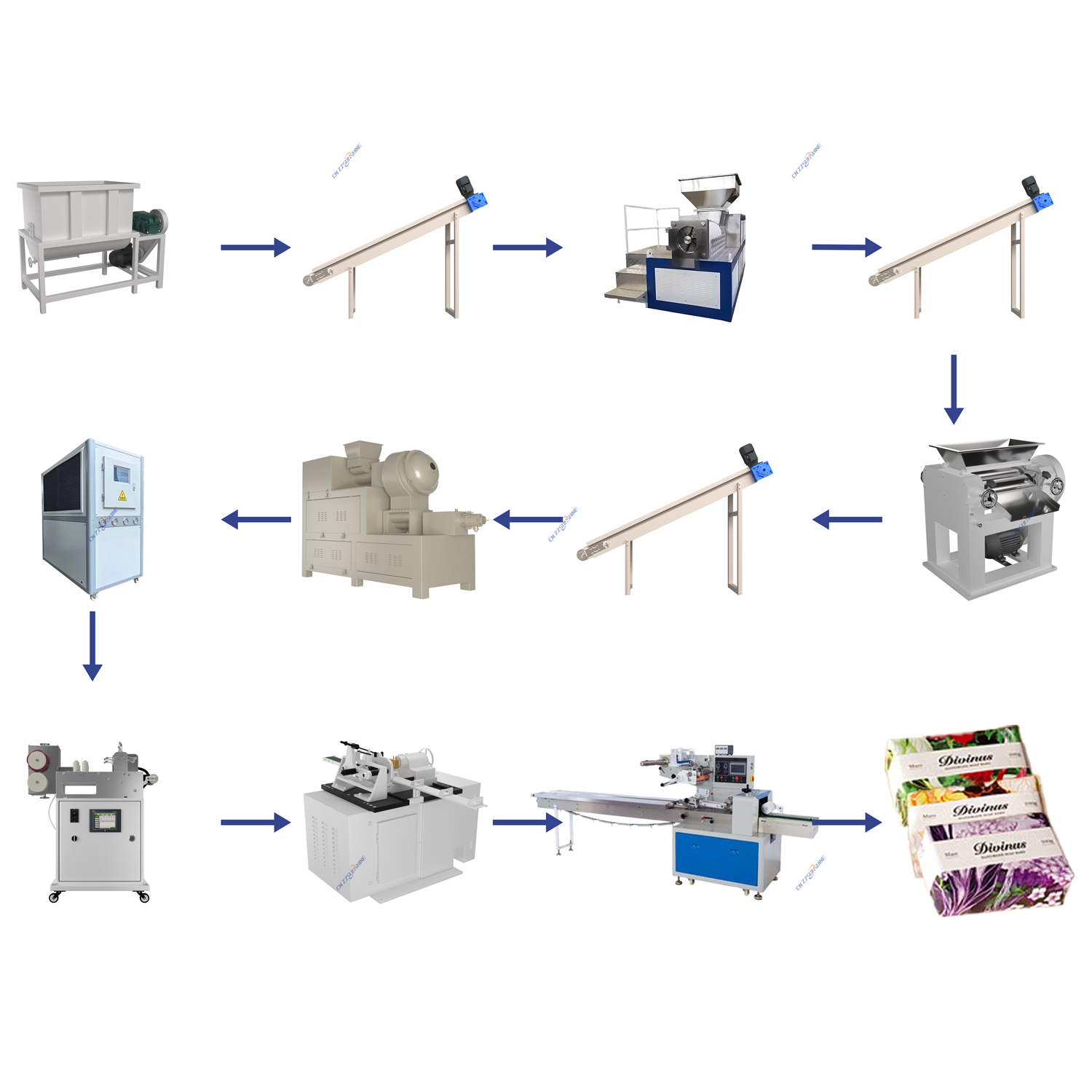

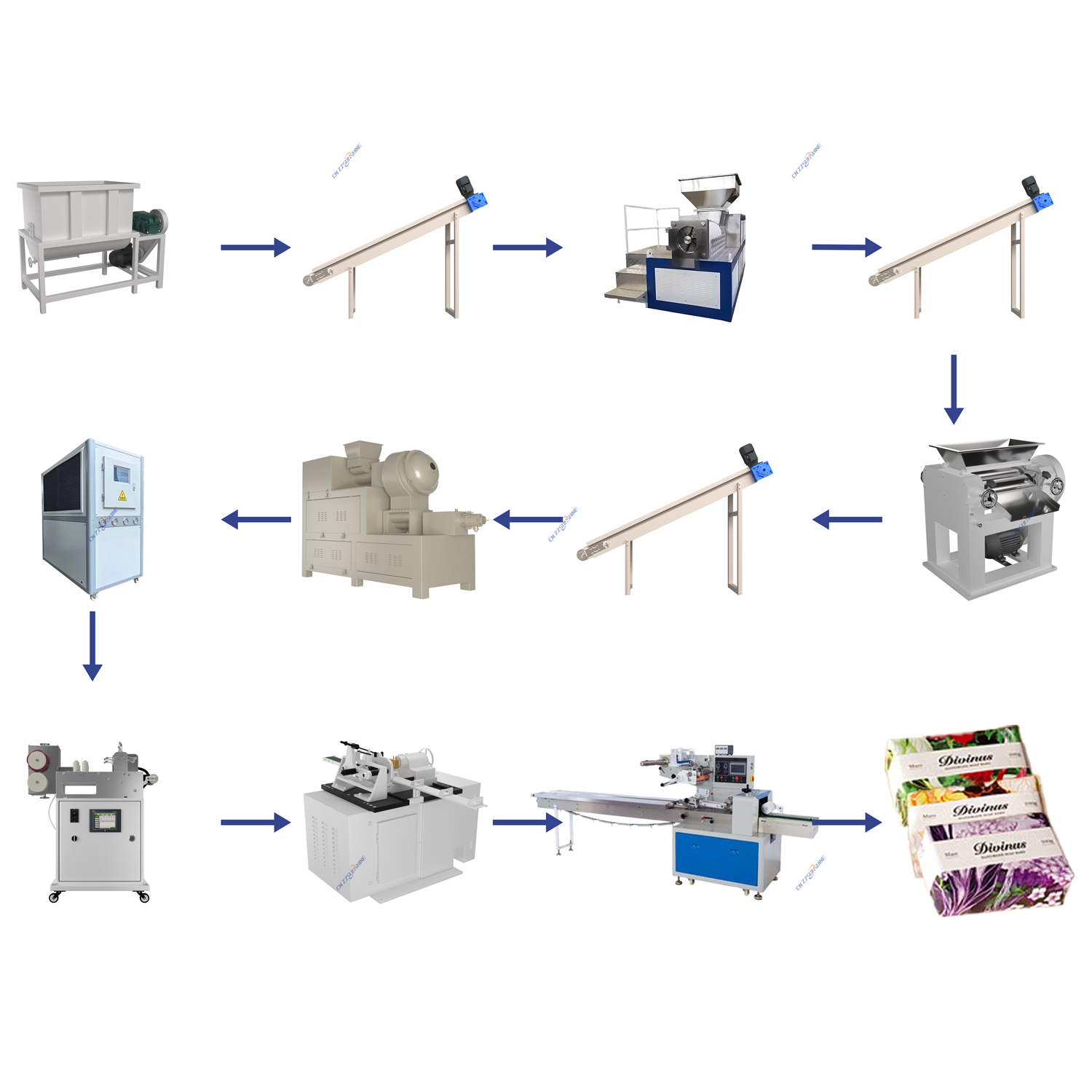

In today’s competitive manufacturing landscape, an automatic soap production line transforms how factories handle high-volume outputs for items like laundry bar soap, bath soap, and beauty soap. This integrated system minimizes manual labor while maximizing throughput, using components such as a vacuum plodder to refine soap consistency and an electric washing soap cutter for precise slicing. Key to its success is the soap mixer, which blends raw materials uniformly to avoid inconsistencies, and a custom soap cutting machine that adapts to various bar sizes without waste. For operations focused on laundry bar soap production line or toilet soap finishing line, this automation reduces downtime and energy costs, ensuring each unit meets strict hygiene standards. Moreover, integrating a reliable industrial chiller for machinery prevents overheating during continuous runs, supporting 24/7 operations. Companies investing in a beauty soap making line often see ROI within months due to reduced errors and faster packaging. By choosing a trusted supplier, factories can customize their setup with OEM three roller grinding mills for added refinement, making the entire process scalable and cost-effective. Ultimately, adopting an automatic soap production line isn’t just about upgrading equipment—it’s a strategic move toward sustainable, high-quality manufacturing that keeps pace with global demand.

Automatic Soap Production Line: Boosting Factory Efficiency with Advanced Technology

Automatic Soap Production Line: Boosting Factory Efficiency with Advanced Technology

Posted Date:

By:

If you’re interested in our soap manufacturing equipment or would like to learn more about customized solutions tailored to your specific production needs, please fill out the inquiry form below with details such as your required capacity, soap type, level of automation, etc. As a professional manufacturer of soap machinery, we’re ready to provide you with comprehensive information and a competitive quotation—welcome to contact us!