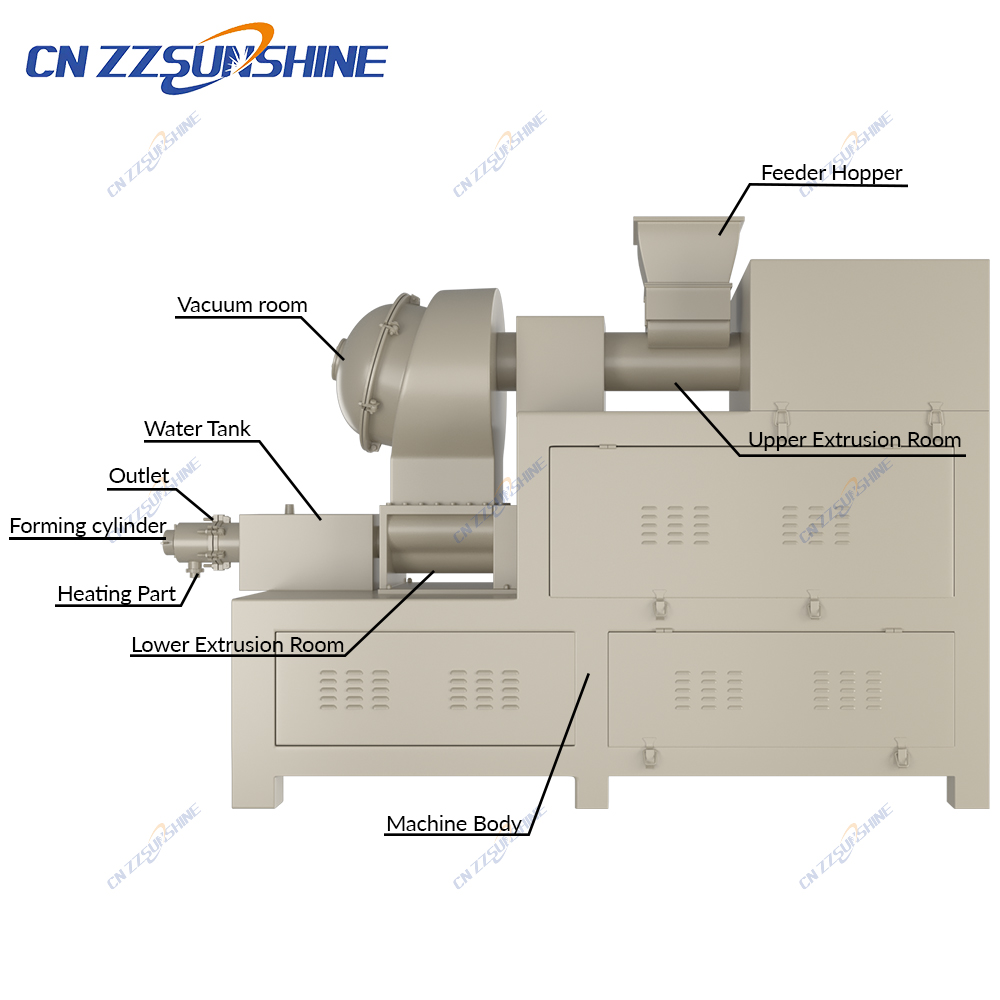

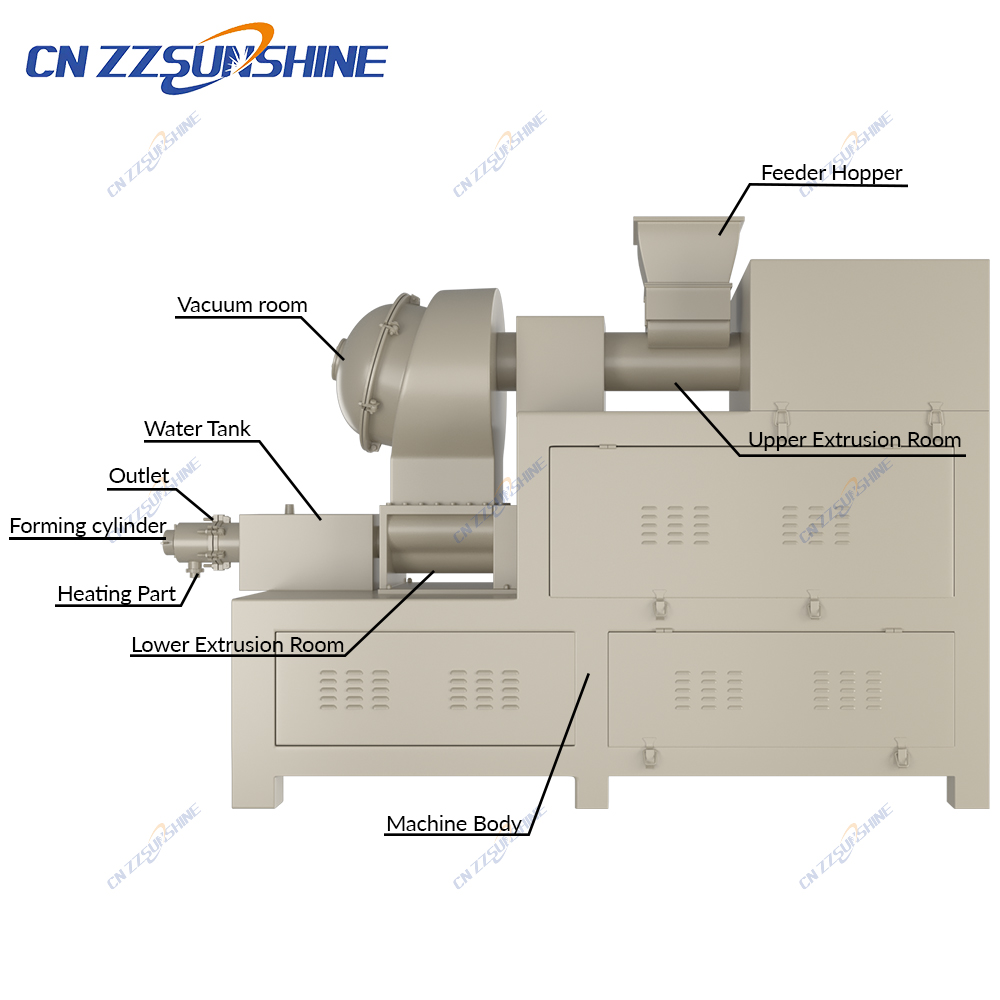

In today’s competitive industrial landscape, an automatic soap production line stands as a cornerstone for manufacturers seeking efficiency and consistency. This integrated system streamlines the entire soap-making process, from raw material mixing to final packaging, reducing labor costs and minimizing human error. Key components like the soap plodder machine ensure uniform extrusion for bar soap, while advanced vacuum plodder technology eliminates air bubbles, enhancing product durability. For instance, in laundry bar soap production lines or beauty soap making lines, the soap mixer handles precise chemical blending, ensuring consistent viscosity and fragrance. The process often incorporates an electric washing soap cutter for accurate sizing, paired with automatic soap cutters to boost throughput. Such systems are vital for high-volume operations, including toilet soap finishing lines and bath soap making machines, where custom soap cutting machines adapt to diverse shapes and formulations. Beyond soap, this automation integrates seamlessly with auxiliary equipment like industrial chillers for machinery to maintain optimal temperatures during cooling phases. Choosing a reliable China soap making machine supplier ensures access to factory price industrial chillers and OEM three roller grinding mills for cosmetics, supporting scalability. Ultimately, an automatic soap production line cuts waste by 20-30%, elevates hygiene standards, and accelerates ROI, making it indispensable for modern factories aiming for sustainability and market leadership.

Automatic Soap Production Line: Revolutionizing Industrial Soap Manufacturing

Automatic Soap Production Line: Revolutionizing Industrial Soap Manufacturing

Posted Date:

By:

If you’re interested in our soap manufacturing equipment or would like to learn more about customized solutions tailored to your specific production needs, please fill out the inquiry form below with details such as your required capacity, soap type, level of automation, etc. As a professional manufacturer of soap machinery, we’re ready to provide you with comprehensive information and a competitive quotation—welcome to contact us!