Unlock Efficiency: The 200 Kg/h Laundry Soap Production Line – Perfect for Small to Medium Scale Manufacturing

For entrepreneurs and businesses aiming to enter the soap manufacturing market or expand existing capabilities without massive overhead, finding the right production solution is key. The 200 Kg/h Laundry Soap Plant, also known as a High Efficiency Small Bar Soap Production Line, offers an ideal balance of output, automation, and investment. This compact yet robust system is specifically engineered for producing high-quality laundry bars efficiently, making it a smart choice for focused production goals.

This streamlined laundry bar soap production line integrates essential machinery to handle the core processes: saponified base preparation, refining, extrusion, cutting, stamping, and packaging. Its design prioritizes efficiency and consistent quality, crucial for building brand reputation in competitive markets.

Core Components Driving Efficiency:

The heart of the line often lies in the refining and extrusion stages. An OEM three roller grinding mill ensures the soap base is thoroughly homogenized and refined, creating a smooth, consistent texture. This refined mass is then fed into a critical component: the soap plodder machine for bar soap. Modern lines typically utilize a Vacuum plodder, which removes air pockets during extrusion. This vacuum process is vital as it results in a denser, harder bar soap with better lathering properties and longer-lasting durability – essential qualities for laundry bars subjected to rigorous use. The extruded soap log emerges ready for shaping.

Following extrusion, precision cutting is paramount. An automatic block cutter machine takes the continuous soap log and slices it into individual billets or blocks with high accuracy and minimal waste. This automation ensures uniformity in size and weight, critical for both cost control and product presentation. Options like pneumatic cutting machines or electronic cutting machines offer reliable, consistent cutting force.

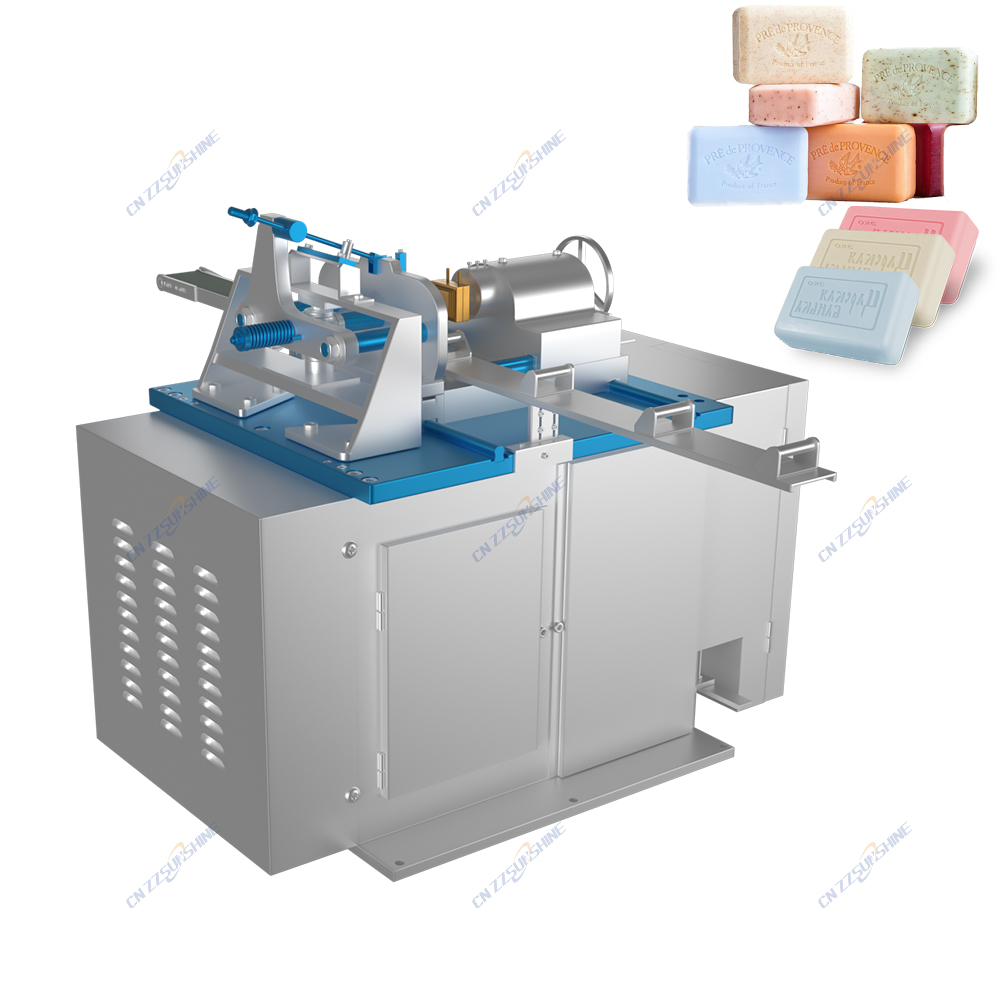

The cut billets then proceed to stamping. An Automatic Printer or Soap Stamping Machine imprints the logo, brand name, or other designs onto each bar. Automation here ensures clear, consistent branding on every single bar, enhancing professionalism. Finally, the finished bars are packaged. A Film Packaging Machine efficiently wraps the bars, typically in polyfilm or flow wrap, providing protection and a shelf-ready appearance. For added flexibility, some lines might incorporate a Semi-automatic Printer for specific packaging formats.

Why Choose a 200 Kg/h Line?

This high efficiency small bar soap production line offers significant advantages:

Optimized Output: Producing 200 kg per hour provides substantial volume for small to medium businesses or dedicated laundry bar lines within larger operations, without the complexity of massive plants.

Automation & Consistency: Key processes like cutting, stamping, and extrusion are automated, minimizing human error and ensuring uniform product quality batch after batch.

Space & Investment Efficiency: Designed as a Mini Soap Production Line or compact laundry soap making line, it requires less floor space and a lower capital investment compared to large-scale systems, offering a faster ROI.

Focus & Flexibility: Primarily geared towards laundry bar soap production, its efficient design allows for potential adaptation or serves as a dedicated line within a facility producing other soap types using separate toilet soap finishing lines or beauty soap making lines.

Conclusion:

For manufacturers prioritizing efficiency, quality, and manageability in laundry soap production, the 200 Kg/h Laundry Soap Plant represents a compelling solution. By integrating core technologies like the Vacuum plodder, automatic block cutter machine, and Automatic Printer within a streamlined Automatic soap production line, it delivers the output and consistency needed for market success at a manageable scale and investment level. This line empowers businesses to produce professional-grade laundry bars efficiently and reliably.